Voting closes soon in the 3D Printing Industry Awards 2023. Have your say now!

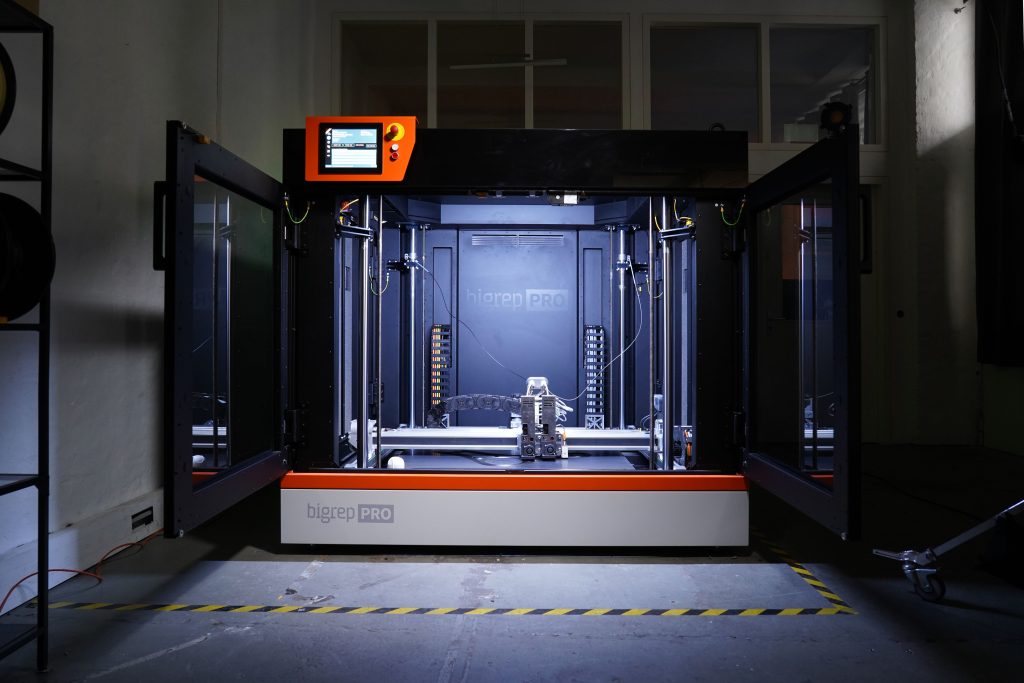

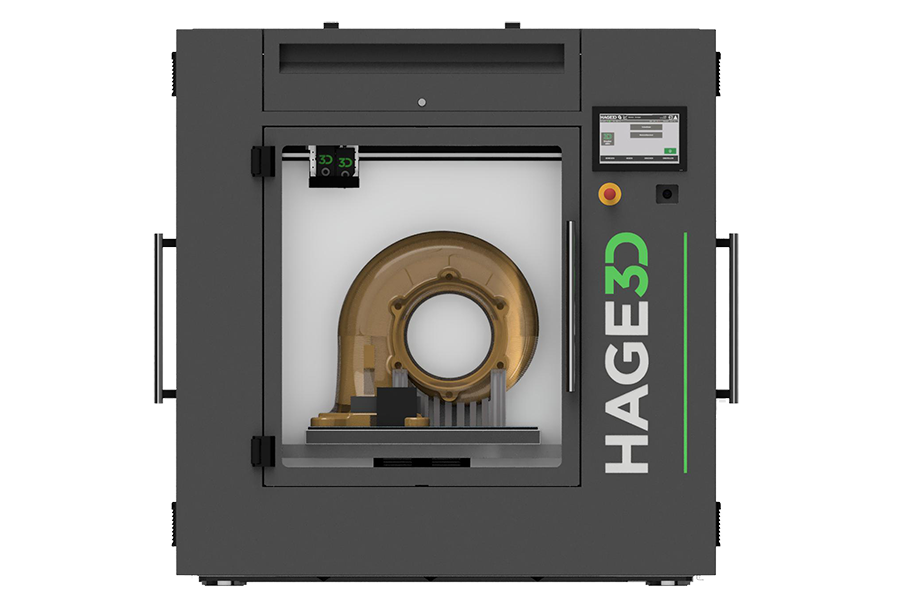

German large-format 3D printer manufacturer BigRep has acquired HAGE3D to broaden its low-to-high-temperature AM solutions, expanding globally with an enhanced reseller network and scalable supply chain.

Bringing together expertise in large-format extrusion-based 3D printing, the partnership solidifies its position with a combined installed base of over 1,000 printers in various industrial sectors. Maintaining confidentiality, the specific terms of the deal have not been disclosed.

Thomas Janics, Managing Director of HAGE3D, says, “With BigRep we have found a perfect partner to accelerate the attractive global growth opportunities in the industrial AM sector. While our focus was previously on the German‐speaking markets, we now can provide our products globally through BigRep´s sales network, adding Graz to map of technology centers next to BigRep’s in Berlin, Boston, Shanghai, and Singapore. Complementing its current low‐temperature and energy‐conscious large-format AM platforms, we will expand BigRep´s portfolio with a range of high‐temperature 3D printers that open a broad spectrum of new applications and markets. It’s a win‐win in R&D, production, and sales. Therefore, we jointly look forward to an innovative, unique, and successful future together.”

Strategic move to redefine large-scale 3D printing

Combining the offerings of BigRep and HAGE3D, the integrated portfolio introduces industrial 3D printers boasting a build volume of up to one cubic meter. What sets them apart is the capability to handle a diverse range of materials—ranging from standard to technical and high-performance thermoplastics. The seamless operation of the 3D printers across low, mid, and high-temperature build chambers provides manufacturers with a versatile solution for complex large-scale functional part production.

Aligned with BigRep’s integrated AM model, including German hardware, intuitive software, quality-controlled filaments, and extensive support, this collaboration aims for global acceptance by incorporating HAGE3D products. Both companies are committed to advancing intelligent Fused Filament Fabrication (FFF) technology for large-format functional parts, aiming to make it the mainstream choice for manufacturers.

Dr.‐Ing. Sven Thate, Managing Director of BigRep, added, “We are excited about the merger with HAGE3D. For our worldwide customers this makes us their local provider of open industrial AM solutions across all temperature levels unlocking almost limitless material options. We expect the AM market to continue its dynamic growth for the foreseeable future, driven by strong megatrends such as digitalization and decentralization of manufacturing. We will capture this opportunity with HAGE3D, who ideally complement our team and portfolio of open AM solutions with its high‐temperature FFF platforms. Together, with similar mindsets of customer centric, data‐driven innovation, we plan to form a European leader pushing the limits of what is possible with FFF.”

Advancing global 3D printing through acquisitions

Solid Solutions’ subsidiary, Solid Print acquired Swedish reseller 3D Verkstan, enhancing its presence in the Nordic region and expanding services. Additionally, Solid Solutions acquired AM services provider 3DPRINTUK, aiming to offer a comprehensive suite of services. These two acquisitions aligning with Solid Solutions’ strategy, diversify and expand its service offerings, fostering international collaboration within the TriMech Group for enhanced customer support and technology deployment.

US 3D printer manufacturer Nexa3D acquired XYZ Printing’s SLS business, with financial terms undisclosed. With this strategic move, Nexa3D gains access to XYZ Printing‘s technology, distribution channels, and services. As part of the agreement, Nexa3D will be incorporating XYZ’s MfgPro230 xS and MfgPro236 xS 3D printers into its growing lineup of powder bed products.

Read all the 3D Printing Industry coverage from Formnext 2023.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Collabosphere by BigRep. Photo via BigRep.