In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features new materials, partnerships, and business deals, and SPEE3D and ASTRO America securing awards.

Read on for the most recent updates from Sintratec, Xact Metal, Marketiger, RICOH 3D for Healthcare, and more.

New materials from Uniformity Labs, AddUp, 6K Additive, and more

Diving into new materials, AddUp joins a $1.5M research contract with the United States Air Force (USAF) and Small Business Innovation Research (SBIR) program, led by REM Surface Engineering (REM). The contract is titled “Development of Manufacturing, Heat Treatment, and Surface Finishing Guidelines to Yield Ready-to-Use IN-718 Additive Manufacturing Components.” The project focuses on leveraging laser powder bed fusion (LPBF) and surface finishing technologies to produce IN-718 components for armament systems. It investigates the impact of heat treatment, printing parameters, and REM’s surface finishing on mechanical properties. AddUp and Zeda support the project, aiming to provide manufacturing guidelines for LPBF to meet USAF’s readiness goals.

Next up, engineered materials company Uniformity Labs has introduced UniJet SS17-4PH Performance, an ultra-low porosity 17-4PH stainless steel powder, for the Desktop Metal Production System. The company aims to provide uncompromised metal additive manufacturing (AM) solutions to the industry. The qualification process on Desktop Metal’s Production System involved extensive evaluation of the physical and mechanical properties of UniJet 17-4PH powder, yielding exceptional results. UniJet 17-4PH exhibits superior uniform powder bed layering, resulting in twice the green strength and an average of 20% less shrinkage compared to other stainless-steel powders approved for use with Desktop Metal’s Production System. These qualities, combined with industry-leading powder bed uniformity, contribute to improved geometric accuracy of sintered parts and reduced breakage during post-print handling and depowdering. As a result, the process yields high-quality parts with increased throughput.

6K Additive recently declared that its environmentally friendly tungsten powder has successfully met the requirements for processing through Wayland Additive’s NeuBeam print process. This achievement opens up possibilities for creating components in the nuclear, aerospace, and hypersonic sectors. With this qualification, it becomes feasible to utilize the challenging-to-process tungsten powder in additive manufacturing, enabling the production of parts for novel nuclear applications, hypersonic technologies, and other aerospace projects that demand high-level heat resistance.

Additionally, Kimya has introduced the Kimya ABS-R 3D filament, a new standard ABS filament composed entirely of post-consumer recycled material. Kimya believes this novel filament promotes the advancement of a circular economy by minimizing CO2 emissions, reducing water and electricity consumption, and lessening reliance on oil resources during production. Acrylonitrile butadiene styrene (ABS) is a thermoplastic polymer known for its lightweight nature, superior impact resistance, and reliable temperature durability. ABS is commonly employed in functional prototyping and enclosure applications across various industries, including appliances, telecommunications, and more.

Emerging partnership news from Sintratec, B9Creations, SLM Solutions, Tekna, and more

Now proceeding with partnerships, Swiss manufacturer of 3D printers Sintratec has formed a partnership with Sun Digital to introduce its 3D printing technologies in Mexico. With over 50 years of experience, the Mexico City-based company specializes in selling and servicing label packaging, and color 3D printers. As the exclusive partner of HP Indigo Digital Presses in the market, Sun Digital has recently launched an Additive Division, “marking its foray” into the 3D printing sector. This collaboration with Sintratec is a significant step for both companies, as it allows Sintratec to establish a foothold in the Mexican market and expand its sales and service network in North America.

Sintratec is strengthening its distribution and service network in Eastern Europe by collaborating with Croatian company 3DPrintaj. This partnership marks a significant milestone as 3DPrintaj becomes the first representative of Sintratec’s SLS (Selective Laser Sintering) systems in Croatia. 3DPrintaj is expanding its range of offerings by incorporating SLS technology into its product portfolio. This expansion complements its existing lineup of FDM and DLP machines from reputable suppliers like Phrozen, Raise3D, and Zortrax. To accomplish this, 3DPrintaj is utilizing the Sintratec All-Material Platform (AMP), which enhances production capabilities. This collaboration enables 3DPrintaj to cater to a wider range of customer demands in the future. For Sintratec, this partnership represents a significant stride into the Eastern European market, marking its debut in countries such as Croatia, Bosnia and Herzegovina, and Slovenia.

Additive manufacturing services provider B9Creations has joined forces with a research team from South Dakota Mines. Their collaboration aims to investigate the root causes of osteoarthritis and lay the groundwork for potential future discoveries that could lead to a cure for this long-standing disease that has challenged scientists for many years.

The research team from South Dakota Mines has made significant advancements in the field of osteoarthritis by utilizing B9Creations’ 3D printing technology. Through their efforts, they have successfully developed and patented a novel technology known as CellWell. Furthermore, they have established a startup company to further explore its potential. CellWell, in conjunction with a 3D printed housing that connects it to other joint components such as bone and synovial membrane models, allows for the examination of cartilage cells in a manner that closely resembles their natural state. This combination of tools provides researchers with unprecedented opportunities to observe and test cartilage cells, leading to invaluable insights into the underlying causes of osteoarthritis that were previously unattainable, says B9Creations.

Industrial metal 3D printer manufacturer AddUp has recently become a member of the Dassault Systèmes 3DEXPERIENCE platform ecosystem. Dassault Systèmes offers a comprehensive suite of applications within the 3DEXPERIENCE platform specifically designed for additive manufacturing. These applications encompass various aspects such as material characterization, customized design, preparation and simulation of build jobs, as well as scheduling and monitoring of shopfloor activities. By utilizing this integrated platform, users can ensure seamless digital continuity throughout the entire lifecycle of parts production. AddUp has developed the Virtual Twin of the FormUp 350, utilizing its dedicated interoperability solution called AddUp NTwin, which allows for seamless integration with the 3DEXPERIENCE platform. AddUp NTwin enables users of the 3DEXPERIENCE platform to effortlessly generate job files, access additional build information, and conduct simulations. Hosted by Dassault Systèmes It is accessible to users within the AddUp community.

AMEXCI AB, a Swedish accelerator for adoption of 3D printing technologies has partnered with AMPOWER, an AM consultancy, to announce their upcoming online training courses. The aim of these courses is to assist both their members and customers in learning and implementing additive manufacturing at a faster pace.

This comprehensive training program comprises five courses tailored for individuals who are new to additive manufacturing, as well as those with intermediate knowledge in the field. The AMPOWER Academy platform was unveiled at Formnext 2022 as an online educational resource, designed to expedite self-paced learning for engineers, purchasers, and quality managers. The platform covers essential subjects related to additive manufacturing, including technology fundamentals, operational principles, common applications, and prevailing market trends. This enables both individual employees and entire organizations to access the online platform and acquire knowledge at their own convenience.

Metal 3D printer manufacturer SLM Solutions has announced a collaboration with the Danish Technological Institute (DTI) to scale up additive manufacturing industrialization. This collaboration aims to transform metal additive manufacturing by establishing superior parameters for SLM machines, particularly the NXG XII 600. DTI is developing faster process parameters for stainless steel 316L and copper alloy CuCr1Zr using their SLM 280 2.0. The focus is on cost-effective production, leveraging SLM Solutions’ open architecture approach. The partnership will explore material development for advanced components with critical electrical and thermal conductivity requirements. It also enables fast production of sturdy stainless steel components.

Tekna has announced its collaboration with TriTech Titanium Parts, a Detroit-based additive manufacturing company to create a novel titanium powder that meets aerospace AS9100 and medical ISO 13485 standards. This high-quality powder is specifically designed to ensure outstanding part quality and mechanical properties. By leveraging Tekna’s industrial-grade titanium powder, TriTech is able to fully utilize binder jet 3D printing technology, enabling the production of customized, lightweight, and strong titanium parts that surpass the limitations of conventional manufacturing methods.

6K Additive, has announced an agreement with Australia-based Surgical Metal Recycling (SMR). This partnership aims to transform the metals supply chain in Australia. One area of focus is advancing the treatment process for surgical implants that have reached the end of their lifespan. Under the agreement, SMR will provide used and out-of-spec implants, swarf, and used metal additive manufacturing powder. This material will be reprocessed utilizing 6K Additive’s UniMelt production-scale microwave plasma platform. Initially, the reprocessing will take place in the U.S., with plans to expand to Europe in the future. The outcome of this process will be the creation of premium powders that can be utilized for additive manufacturing to produce new parts. The ultimate goal of the partnership is to establish a sustainable and circular supply chain, enabling the creation of certified implants from existing parts.

AMAZEMET and AXT have formed a strategic partnership, marking AMAZEMET’s introduction into the Australian market. In doing so, AXT will expand its offerings and unlock new business prospects by incorporating AMAZEMET’s products. The partnership entails the distribution of AMAZEMET’s product range, which includes the rePowder ultrasonic atomizer for metal powder production, the inFurner high vacuum furnace, and the safeEtch device for automated removal of fixtures from 3D printed metal components. Through this collaboration, AXT can provide its customers with access to novel technologies for the additive manufacturing of metal parts.

Powder bed fusion (PBF) 3D printers provider EOS has announced that it will be further strengthening Indiana Tech‘s STEM program. Through this partnership, EOS will supply the university with two highly advanced 3D printers: the FORMIGA P 110 Velocis and the EOS M 290. Indiana Tech’s Talwar College of Engineering and Computer Sciences is set to enhance its additive manufacturing capabilities through the addition of two advanced 3D printers. The FORMIGA P 110 Velocis, a polymer SLS printer, offers high precision and resolution, making it suitable for prototyping, tooling, and final part production across various applications. On the other hand, the EOS M 290, a metal DMLS printer, creates high-performance metal components. These printers will play a vital role in providing students with practical experience in additive manufacturing. Moreover, they will support the university’s biomedical and advanced manufacturing programs.

British multinational manufacturer GKN Aerospace and Materialise, a 3D printing service provider have agreed to collaborate through a Letter of Intent (LOI). Their joint efforts focus on enhancing the research, design, and manufacturing of polymer 3D printed components for the aviation sector. The partnership aims to expedite the certification process for additive manufacturing and explore new possibilities for producing functional and flight-critical aerostructures, taking advantage of the unique benefits offered by this manufacturing method.

“This powerful alliance aims to leverage our combined expertise and the exceptional benefits of 3D printing to push the boundaries of innovation in the aeronautics industry,” said Jurgen Laudus, Vice President of Materialise Manufacturing. “Together, we aim to drive technological advancements, respond more effectively to customer requirements, and shape the future of aerospace manufacturing.”

Industrial 3D printer manufacturer Roboze and Magnaghi Aeronautica signed an MOU at the Paris Air Show 2023. The focus is on weight and emissions reduction, and certifying the production process using Roboze 3D printing. Previously, polymer 3D printing was limited to aerospace interiors. Roboze and Magnaghi aim to produce class 2 and 3 landing gear components, standardizing manufacturing and qualification for 3D printing.

Business and acquisition deals from Xact Metal, Nexa3D, Paul Horn, and more

Metal 3D printer manufacturer Xact Metal has reached a significant milestone by receiving its 100th printer order. This achievement follows the successful launch of the XM200G, its second metal 3D printer, in 2021, expanding its customer base.

“Our success in reaching this milestone is a testament to the hard work and commitment by the Xact Metal team and our global network of sales partners, who share our passion for expanding access to this technology while providing the best possible experience for our customers,” said Juan Mario Gomez, CEO of Xact Metal. “We’ve been able to realize our original hypothesis, which was that metal 3D printing has a significant place in the future of manufacturing for small-to-medium-sized companies when there is an avenue for increased adoption. By designing Xact Metal products for ease of use, accessibility, and affordability, we have provided the opportunity for adoption to over 100 customers and counting.”

RE3DTech, Stanfordville Machine & Manufacturing, Phoenix Proto Technologies, and GoProto, have joined forces to form UPTIVE. This merger brings together their expertise in additive manufacturing, CNC machining, sheet metal fabrication, rapid prototyping, post-processing and finishing, injection molding and tooling. UPTIVE’s dedicated team provides personalized guidance and precise development of custom parts, turning their “clients’ visions into reality.” The company has unveiled its new branding and improved online presence at uptivemfg.com, where customers can access many resources, including quote requests and a knowledge base library.

Carbide tool manufacturer Paul Horn has adopted the Solukon SFM-AT350, developed by Solukon Maschinenbau GmbH, to automate the depowdering process for its tool components manufactured using selective laser melting. The Solukon SFM-AT350 is a fully automated depowdering system that utilizes rotation, vibration, and compressed air to effectively remove residual powder from intricate metal parts. Specifically designed for medium-sized parts weighing up to 60 kg, the system can be applied to depowder a range of materials such as stainless steel, titanium, tool steel, and aluminum.

“The Solukon system increases safety (explosion protection) because we can also use it to depowder metal parts made of reactive materials in a protective gas atmosphere,” said Bartkowiak. Bartkowiak and his team also rely on the Solukon system for its contribution to sustainability.

Next up, high-speed resin 3D printer manufacturer Nexa3D has completed the acquisition of Addifab, a company specializing in freeform injection molding. This strategic move enhances Nexa3D’s additive manufacturing capabilities, enabling it to achieve faster and more efficient production of high-performance parts.

“We are very excited to welcome the entire Addifab team to the growing Nexa3D family of people, products and partners democratizing access to dissolvable tooling for same day complex molded parts with hundreds of industrial plastics,” said, Avi Reichental, Co-Founder, Chairman and CEO of Nexa3D.

3D printer OEM Stratasys has successfully finalized the acquisition of Covestro AG‘s additive manufacturing materials business. The acquisition is expected to have an immediate positive impact, incorporating R&D facilities, global sales teams, and extensive intellectual property assets. Stratasys has gained approximately 60 AM materials and a significant IP portfolio comprising numerous patents and pending patents. These new resources and talents will enable Stratasys to explore novel applications in critical technology sectors like stereolithography, P3/DLP, powder bed fusion, and SAF technology. Moreover, they will complement Stratasys’ existing expertise in PolyJet and FDM technologies, strengthening the company’s materials capabilities.

Aspect Biosystems and Novo Nordisk have unveiled a collaboration worth $2.6 billion to jointly work on the advancement of bioprinted tissue therapeutics specifically aimed at addressing diabetes and obesity.

Under the agreement, Aspect will receive an initial payment of US$75 million, as well as potential payments of up to US$650 million per product for a maximum of four products. This brings the total value of the deal to over US$2.6 billion, in addition to tiered royalties based on product sales. This collaboration will leverage Aspect’s proprietary bioprinting technology alongside Novo Nordisk’s expertise in stem cell differentiation, along with their capabilities in cell therapy development and manufacturing. The primary focus will be the development of bioprinted tissue therapeutics that can effectively regulate blood glucose levels without the requirement for immunosuppression. This novel approach holds the potential to revolutionize treatment options for individuals living with type 1 diabetes globally.

Additive manufacturing service provider ADDMAN has announced its participation in the Roboze 3D Parts Network at Rapid+TCT 2023. This strategic move aims to enhance ADDMAN’s industrial manufacturing capabilities by incorporating additive manufacturing systems into their operations.

“We are pleased to become a part of the Roboze 3D Parts Network,” says Joe Calmese, CEO of ADDMAN. “We found a partner in Roboze who shares our vision for the present and future of manufacturing – utilizing technology and innovation to address the challenges we face. The shift towards digital manufacturing is becoming increasingly important in light of changing market demands and environmental concerns, and we believe that Roboze can help us achieve the best for our customers.”

The US Navy has selected SPEE3D‘s metal cold spray additive manufacturing (CSAM) technology for a project led by Naval Sea Systems Command (NAVSEA) focused on Expeditionary Maintenance and Sustainment. The objective of the project is to develop materials that meet the high-quality standards of the Submarine Safety Program (SUBSAFE).

The Applied Research Laboratory of the Pennsylvania State University (ARL/PSU), a trusted partner of NAVSEA in cold spray technology, has subcontracted SPEE3D for the project. This collaboration represents the first exploration of cold spray additive manufacturing as a potential method for producing SUBSAFE-compliant components. Working alongside the US Navy and ARL/PSU, SPEE3D aims to develop a novel approach for the rapid manufacturing of essential submarine system parts using its technology.

Multi-material 3D printer developer Inkbit has announced the availability of its 3D printing services. Manufacturers who require intricate geometries and multi-material parts for their polymer products now have the option to obtain prototypes and production volumes without investing in an Inkbit Vista System.

Inkbit’s technology allows for native multi-material printing, enabling the creation of complex structures with integrated soft gaskets. The Inkbit process incorporates real-time 3D inspection, ensuring exceptional accuracy and consistent precision across all components on the print bed. As a result, these components fit together seamlessly during assembly. With Inkbit’s advanced technology and commitment to meticulousness, customers can have full confidence in the consistent delivery of precise and high-quality results.

US 3D printer manufacturer nano3Dprint has revealed a strategic distribution partnership to expand the availability and accessibility of nano3Dprint’s 3D printing technologies in the Japanese market. Japanese firm System Create, will serve as the distributor for nano3Dprint’s A2200 3D Multi-material Electronics 3D Printer and B3300 Dual-Dispensing 3D Printer, catering to customers across Japan.

“The volume of 3D printer sales is expanding significantly. The driving factors are shorter product development times, cost savings and strong pushes for automation,” said Renato Sugiyama, Global Sales Assistant, at System Create Co.

Austrian ceramic 3D printing company Lithoz has delivered a CeraFab S65 System 3D printer to WZR ceramic solutions GmbH, a material development service provider in ceramic 3D printing. A Rheinbach-based company is using high-precision Lithography-based Ceramic Manufacturing (LCM) technology to create complex cerium oxide components for the “Redox3D” project. This initiative aims to generate green hydrogen independently from fossil fuels in solar tower power plants. By employing 3D printed ceramics and harnessing sunlight, this solar-thermochemical process is a key solution for achieving zero-emission societies.

Fast-growing production and prototyping manufacturer, Rennscot MFG, has acquired the EOS M 300-4, a high-productivity direct metal laser solidification (DMLS) 3D printer. This addition strengthens Rennscot MFG’s comprehensive manufacturing capabilities, which encompass design, product development, prototyping, and production using both traditional and 3D printing methods. As a result of this partnership, EOS has welcomed Rennscot MFG as the latest member of its Service Provider network.

“After visiting EOS’ facilities in Germany, it was clear that an EOS machine was the right choice for us,” said David Bamforth, Rennscot MFG president and CEO. “This technology allows us to create complicated parts that couldn’t be produced using traditional manufacturing methods. Not to mention, this technology allows our customers to have a single source for highly complex additive parts that may also require post-machining.”

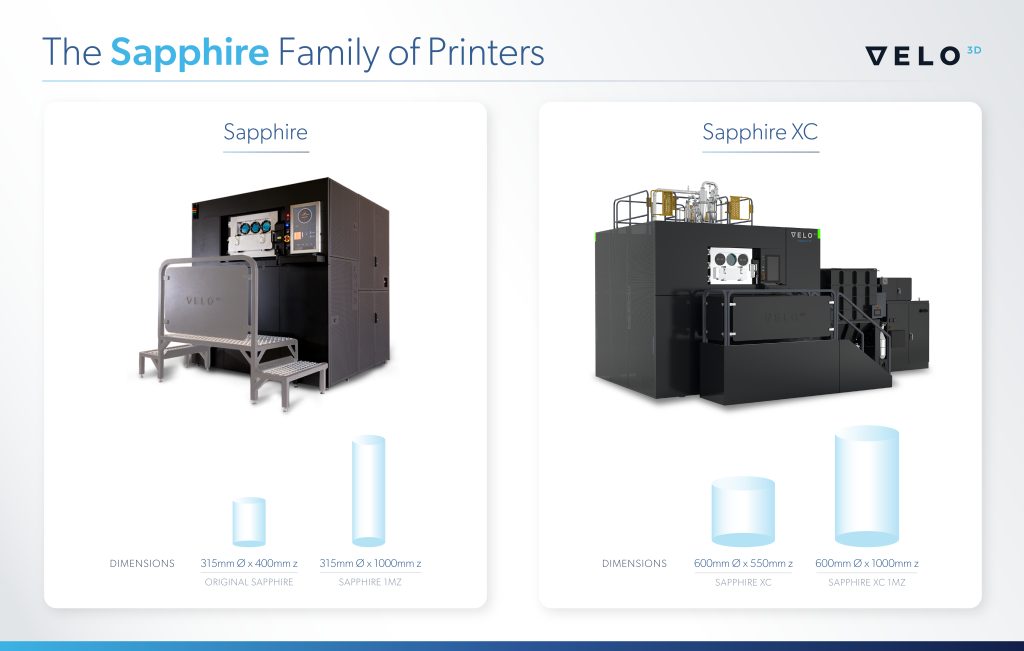

Metal 3D printer manufacturer Velo3D recently announced that Avio S.p.A., an aerospace company listed on the Italian Stock Exchange, has acquired a Sapphire XC 1MZ 3D printer and an original Sapphire 3D printer. These additions will aid in the development and production of Avio’s propulsion systems, while also contributing to the progress of the space industry. Velo3D’s solution was chosen for its capacity to manufacture high-quality parts with optimized geometries, ensuring superior performance. The Sapphire XC 1MZ 3D printer offers a significant advantage with its large build volume. Both printers are calibrated to produce parts using a nickel-based alloy known for its strength and resistance to corrosion, even under extreme temperatures.

“Avio is one of the leading space companies in Europe and we are thrilled to partner with them in their pursuit of groundbreaking propulsion systems,” said Benny Buller, Founder and CEO of Velo3D. “They work with some of the most innovative companies and agencies in Europe and around the world to provide them with the technology they need to reach space. The Sapphire XC 1MZ will help Avio further accelerate the development of its propulsion systems and contribute to the ongoing transformation of the space industry.”

RICOH 3D for Healthcare receives FDA 510k certification

RICOH 3D for Healthcare has received FDA 510(k) clearance from the U.S. Food and Drug Administration for expanding its diagnostic applications. These include patient-specific anatomic modeling in various areas such as genitourinary, neurological, cardiovascular, gastrointestinal, and breast applications.

“Receiving the expanded 510(k) clearance for anatomic modeling of soft tissue is an exciting milestone for Ricoh as we continue to lead the way in offering democratized access to patient-specific 3D-printed models in healthcare,” said Gary Turner, managing director, Additive Manufacturing, North America, Ricoh USA, Inc. “As a manufacturer of precision additive medical devices, Ricoh offers one of the broadest scopes of FDA-cleared 3D models for anatomic regions and a wide range of print materials available for diagnostic use – which combine to improve outcomes, enhance the patient experience and increase opportunities for physician education and training.”

Novel software from Marketiger and Creaform

3D printing solutions provider Marketiger is assisting customers in simplifying and reducing costs associated with mass customization applications. By leveraging its design proficiency and a novel integrated solution combining software and production, Marketiger enables this transformation. Its customization software facilitates a seamless workflow encompassing asset importing, 3D printing, shipping, and billing. This software-integrated production model offers brands an efficient means to generate additional revenue streams and enhance customer interaction using their existing or prospective 3D assets.

Creaform, a unit of AMETEK, Inc., has launched VXelements 11, an anticipated upgrade with new features and improved performance. The major change is seen in VXelements’ dimensional inspection module, VXinspect, which is now split into two modules: VXinspect|Analysis and VXinspect|Quality Control. Both modules are optimized for different phases of manufacturing quality control. VXinspect|Analysis is a user-friendly software for streamlined dimensional root cause analyses, while VXinspect|Quality Control is a comprehensive 3D inspection software for advanced quality control in production.

Insights obtained from additive manufacturing-related research

According to a recent investigation conducted by the Chemical Insights Research Institute (CIRI), it has been discovered that 3D printing can emit various harmful pollutants into the atmosphere. These pollutants include volatile organic compounds (VOCs), ultrafine particles, and metal aerosols. Exposure to these pollutants can lead to several health issues such as respiratory irritation, asthma, cancer, and reproductive disorders.

The study was carried out within a university maker center and revealed that the levels of VOCs in rooms where 3D printers were operational were up to 100 times higher compared to other areas. Furthermore, the study observed significantly elevated levels of particles, some as small as 0.1 micrometers in diameter. These minuscule particles have the ability to be inhaled deeply into the lungs, thereby posing severe health risks.

Binder jetting is an additive manufacturing method gaining popularity due to its cost-effectiveness and material variety. However, it is slower than traditional methods. A study suggests a solution: adaptive slicing. By adjusting layer thickness based on complexity, printing time can be reduced without compromising quality. Researchers from Ondokuz Mayıs University used adaptive slicing to print samples, resulting in 38% fewer layers and significant time savings without quality loss. They also developed a binder algorithm to improve part quality. Adaptive slicing shows promise for speeding up binder jetting, with potential for further advancements.

Researchers from KU Leuven, Thomas More University, the Belgian Welding Institute npo, and Sirris have made advancements in enhancing the quality of additively manufactured parts. Their research carried out under the “Ad-Proc-Add project,” focused on the additive-subtractive manufacturing process chain (ASM). Notably, the project revealed that the parameters of the WAAM process play a significant role in determining effective wall width, surface quality post-deposition, and the amount of material removal required during post-processing. To further investigate the impact of different processes on final part properties, the researchers developed multi-sensor platforms. These platforms enabled monitoring of current, voltage, gas flow rate, and temperature, facilitating the evaluation of WAAM process stability. This approach proved effective in mitigating material defects and enhancing surface performance.

3D printing applications news

Moving forward with novel applications, Ada Hefetz, a popular wedding dress designer based in Israel, has introduced a captivating collection using Stratasys’ direct-to-textile 3D printing technology. Showcased at Milan Design Week, the three dresses are inspired by Hefetz’s Flower of Life theme. Created with Stratasys’ 3DFashion technology, they celebrate the matrimonial union and the circle of life. The dresses feature intricate geometrical shapes representing the Flower of Life, combined with Hefetz’s lily design. Stratasys’ J850 TechStyle 3D printer, using translucent VeroVivid resin, provides over 500,000 unique colors and varying flexibility for different textures and finishes.

High Productivity Wire Arc Additive Manufacturing (HPWAAM) group, has announced it has successfully demonstrated significant advances in technical capability which will enable additive manufacturing to play a greater role in the future of the industry. They aim to industrialize HPWAAM with thermal control and variable resolution for large-scale engineering components. Supported by £1.2 million in funding from Innovate UK, the project involves seven specialized organizations and is scheduled for completion by 2023. The collaboration builds on Cranfield University‘s research, exploring commercial opportunities and addressing sustainability concerns. End users will develop updated Designs for Additive Manufacturing frameworks to transform existing components.

Aniwaa announces technological advancements

Aniwaa, an online marketplace for AM and 3D capture solutions, has unveiled its first AM hardware landscape infographic.

This visual representation showcases over 500 active AM hardware manufacturers, categorized by materials, technology, and other factors. According to the company, the infographic reveals that polymer 3D printers are dominant, accounting for a substantial 57% of AM hardware manufacturers. Metal 3D printers claim the second spot with a 27% representation. The remaining 16% encompasses a diverse range of AM technologies, including ceramics, composites, and bioprinting. Notably, the infographic highlights the increasing popularity of PBF technology, which is now offered by 35% of manufacturers, reflecting an increase from 25% in 2022. Fused deposition modeling (FDM) emerges as the second most popular AM technology, with 28% of manufacturers providing it.

Zortrax introduces metal 3D printing option

Zortrax is introducing a metal 3D printing option for its desktop M300 Dual 3D printer. This industrial-grade machine supports single- and dual-extrusion modes and is compatible with a wide range of materials, including basic filaments, flexible materials, Nylon, and reinforced polymers. To enhance its capabilities, Zortrax offers two kits: Full Metal Package 316L and Full Metal Package 17-4 PH. These kits include BASF Forward AM’s metal-polymer filaments, such as Ultrafuse 316L and Ultrafuse 17-4.

“Zortrax M300 Dual is a truly universal machine, which combines a large workspace, single- and dual-extrusion modes, intuitive interface, and a very wide range of ready-to-use, calibrated material profiles. We’re now adding an option of metal 3D printing to this desktop printer with two comprehensive sets: Zortrax Full Metal Package 316L and Zortrax Full Metal Package 17-4 PH, encompassing everything that’s necessary to start metal 3D printing and to ensure fully functional metal parts, which exhibit the properties of steel,” says Michał Siemaszko, Head of Research and Development Department at Zortrax.

Awards news from SPEE3D and ASTRO America

SPEE3D has been awarded as a winner in the Office of the Secretary of Defense Manufacturing Technology (OSD ManTech) “Point of Need Challenge.” The challenge aims to find solutions that can assist deployed forces in challenging environments. The program will receive an investment of approximately $2.5 million, with additional cost sharing of $700,000 from industry partners.

“Given our proven track record of working with the military in very hot and dry environments, we look forward to demonstrating our expeditionary manufacturing and repair capabilities in sub-freezing conditions,” said Byron Kennedy, CEO of SPEE3D. “We are honored to work with the OSD to showcase our patented Cold Spray Additive Manufacturing technology.”

ASTRO America has been awarded a $1 million grant from the U.S. National Science Foundation‘s Regional Innovation Engines program. ASTRO America is one of over 40 teams to receive the inaugural NSF Engines Development Awards. The grant aims to promote collaboration and create opportunities in economic, societal, and technological sectors. ASTRO America’s initiative, titled “Advancing Additive Manufacturing Technologies,” focuses on accelerating the adoption of 3D printing in supply chains and enhancing capabilities in the aerospace, defense, and energy industries. The project includes a partnership with major corporations and leading minority-serving institutions to support small and medium-sized suppliers in transitioning to additive manufacturing.

Replique closes seed funding round

Replique has recently become an independent entity after separating from Chemovator, the business incubator of BASF. To support its growth, Replique has successfully concluded a late seed funding round. The investment was led by digital technology investor STS Ventures. Replique’s core offering is a secure 3D printing platform that enables sustainable spare part management and small-scale production.

“We see a lot of startups with promising ideas, but Replique stood out to us as a game-changer in the manufacturing industry. Their innovative industrial 3D printing platform has the potential to disrupt the industry and we are excited to support their growth and expansion in the future. Besides the right solution, Replique also brings the right mindset and an excellent team to the table,” says Oliver Kaul, partner at STS Ventures.

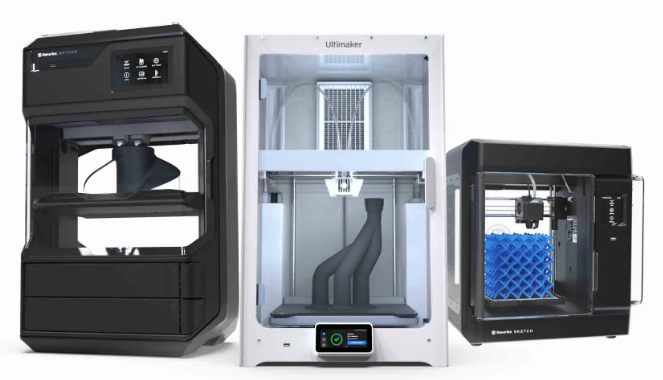

UltiMaker GB announces distribution deal

Desktop 3D printer distributor UltiMaker GB has announced the addition of the new UltiMaker Method and Sketch product lines to its network. This expansion is a significant milestone for UltiMaker GB as it nears its 10-year anniversary as the exclusive distributor. The UltiMaker Method series combines industrial-grade capabilities with desktop convenience for exceptional quality. The Sketch series caters to the education market with user-friendly 3D printing solutions for creativity and prototyping.

“We are incredibly proud and excited to expand our distribution portfolio to include the UltiMaker Method and Sketch product lines,” said Paul Croft, Director of UltiMaker GB. “As we approach our 10-year anniversary, this significant milestone reflects our commitment to offering the best 3D printing solutions to our customers. We are grateful for the support of our reseller network, which has been instrumental in our success so far.”

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.