Materialise, a global leader in 3D printing software and services, has released its Process Control software for metal 3D printing and the Build Processor Software Development Kit (BP SDK). By utilizing automated quality control and configuring their 3D printer parameters, the new technologies enable additive manufacturing (AM) customers to take complete control of the 3D printing process.

“Materialise Process Control uses artificial intelligence to automate quality control, helping our customers save significant time and money,” said Materialise’s CTO, Bart Van der Schueren.

AM service providers are pressured to fulfill escalating part quality and cost standards. Monitoring and regulating the 3D printing process is crucial to this endeavor. Still, AM users need the right tools to avoid failed builds, hidden flaws in their parts, and 3D printing settings that don’t work for AM applications. These problems waste machine time, materials, and post-processing capacity, resulting in extra expenses.

The Advantage of Automatic Quality Control

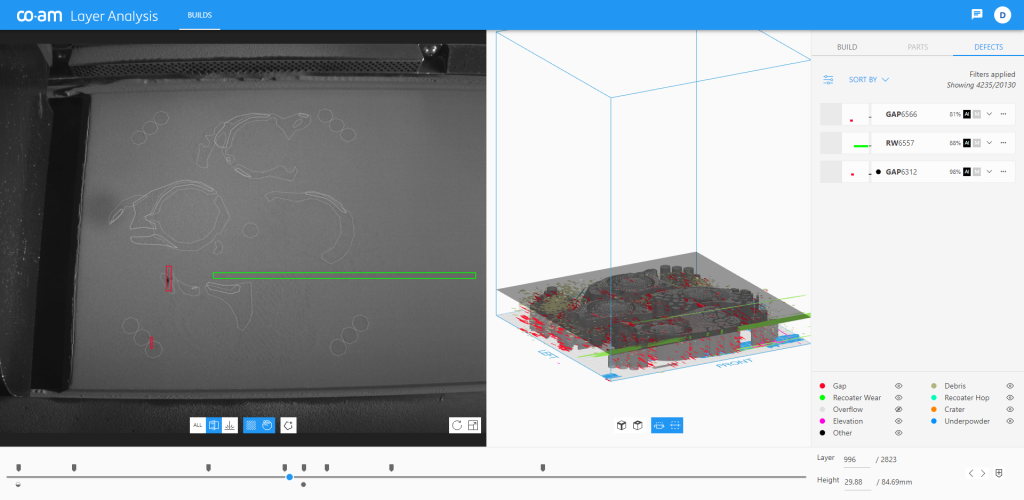

Materialise Process Control lets businesses control quality using data collected during 3D printing. By analyzing and correlating layer data from the 3D printing process, users can find problematic parts before post-processing and quality inspection, which can add 30% to 70% to the cost of making a part. Users can find the root cause of errors faster by looking at the layer data. This lets them improve the process and change the 3D printing settings. Early identification of scrap, and root cause analysis, help lower the cost per component by cutting down on the amount of waste and the number of expensive quality control operations that need to be done after processing.

CTO Van der Schueren said, “Through collaborations with partners like Phase3D and Sigma Additive Solutions, AM users benefit from a technology-agnostic innovation that offers unparalleled insights into their 3D printing process for continuous improvement.”

Although most 3D printed components have hundreds of layers, evaluating them manually is time-consuming and prone to human error. Materialise Process Control automates the process, giving workers more time to improve the AM procedure. During the 3D printing process, artificial intelligence is used to look at 2D photos of the powder bed. Materialise is working with Phase 3D and Sigma Additive Solutions, Inc. (NASDAQ:SASI) to combine supplementary data and give a comprehensive understanding of the 3D printing process. Phase 3D technology offers height mapping, a kind of topographic layer data. At the same time, Sigma Additive Solutions gives heat data from the melt pool, the region where the material is melted during metal 3D printing.

Materialise Process Control is both a part of CO-AM, Materialise’s all-in-one 3D printing software platform, and a separate piece of software that can be used independently. Partners can add their own monitoring software and software to an open software solution.

Improving the 3D Printing Process

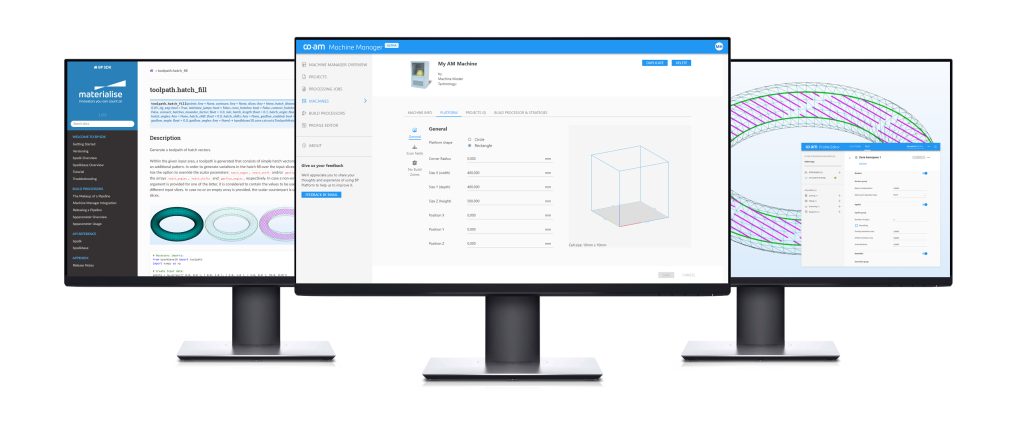

A build processor (BP) links 3D printers to tools like Materialise Magics that help prepare data. It handles 3D printer-specific data and allows users to modify build settings, which impact the speed at which a 3D print job is completed and define component attributes like density and surface quality. Suboptimal build parameters raise the cost per component by prolonging build tasks, increasing post-processing time, and increasing scrap rates.

“More and more AM users want to scale up their activities and serve the demand of quality end-part manufacturing. Very often the standard build parameters of a 3D printer don’t match their needs,” shared Karel Brans, Senior Director Partnerships at Materialise. “They are looking for ways to improve the machine utilization rate and achieve consistent quality. With a BP developed for a specific use case, you can push productivity and quality to a whole new level.”

Previously, it was quite challenging to construct BPs or modify them for specific purposes. The BP SDK provides a flexible method for achieving this. Machine suppliers and manufacturing companies that do research and development can use the development platform as a toolkit, rely on Materialise’s additive manufacturing (AM) skills, or choose to work together. With proven BP technology, businesses can speed up the time it takes to make a new product, add their own APIs, and create new intellectual property. This open development method makes it easier for people to work together and can help BPs become more diverse and better at what they do.

The BP SDK allows AM users to install BPs suited to their needs. For an AM application, a customized BP uses print settings that find the best balance between the cost and quality of the parts. It lets customers make many of the same or customized goods with consistent quality, less waste, and a shorter lead time. Improving how 3D printing works will make more AM use cases possible and make it more likely that businesses will adopt the technology. With the BP SDK, you can make build processors that give you full access to CO-AM and Materialise Magics.

Quality Control in Additive Manufacturing

TÜV SÜD, a German technical service company, gave insights into the importance of quality assurance for additive manufacturing and its importance if users wish to reach serial production with AM.

Based on DIN SPEC 17071, the company has made a certification system for additive manufacturing facilities. This will help manufacturers set up serial additive manufacturing. When it comes to safety components and other regulated areas, serial production of things made with additive manufacturing has often failed because of a lack of experience and knowledge. For high-quality parts, there needs to be a full description of the production process and continuous quality assurance. This means that the quality characteristics and test methods must be described in detail. DIN SPEC 17071 tells users and manufacturers how to set up production lines in a few months instead of years, including how to minimize risk and make sure quality. The certification scheme helps manufacturers to demonstrate their implementation of DIN SPEC 17071 and their commitment to ensuring reliable and assured product quality to their customers and business partners.

Recently, 3D Printing Industry interviewed Hexagon to understand how the Nexus platform can be used in an industrial 3D printing workflow. Hexagon and Microsoft have teamed up to launch Nexus, a digital platform for manufacturing that lets engineers and manufacturers work together in real-time during all stages of a product’s lifecycle, from design and engineering to production and quality. The platform’s Design for Additive Manufacturing (DfAM) capabilities will be particularly useful to the 3D printing industry, addressing the data silos and limited collaboration that has hampered progress in the sector. Nexus includes three apps at launch, with new features set to be added regularly.

The first “solution” that Nexus adds is for DfAM. It combines Hexagon’s MSC Apex Generative Design software with AM Studio from CADS Additive and Materials Connect over the cloud. Once the design phase has been completed, Hexagon’s Simufact Additive process simulation software runs simulations on the part, checking its manufacturability. This lets the part’s design and build preparation be changed quickly to meet the customer’s needs and ensures it can be made. Nexus’s DfAM also offers an interactive three-dimensional whiteboard, enabling all project members to perform live project reviews with real-time annotation, sketching on the 3D model.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Materialise Process Control. Image via Materialise.