The leadership of BASF Forward AM, headed by CEO Martin Back, has acquired BASF’s additive manufacturing business to form Forward AM Technologies (also known as Forward AM).

Billed as the “only full AM portfolio provider,” the newly independent company combines BASF’s 3D printing materials and solutions with its Sculpteo service bureau business.

According to Forward AM Technologies, the decision to carve out from the global chemical production company was made to enhance customer support, accelerate innovation, and improve market responsiveness. The new firm retains control of its prior intellectual property (IP) and supply chain and will continue to provide its established products and services to its global customer base.

According to Back, BASF collaborated with Forward AM Technologies to support the Management-Buy-Out process. This reportedly enabled job security for existing employees and allowed the company to retain its advanced 3D printing technologies.

“By working together, we could ensure that our team of experts and the innovative tools currently in place can continue to provide leading AM solutions to the manufacturing industry in times of volatility,” added Back.

BASF’s departure from additive manufacturing is significant, leaving the 3D printing industry without a major chemicals company.

While Saudi Arabia-based chemical producer SABIC continues to operate, its AM offering mainly relates to pellets. Elsewhere, sources suggest Belgian chemical firm Solvay’s additive materials team was spun out into an independent venture called Syensqo in 2023. Henkel, though a major materials specialist active in 3D printing, is not a base chemical producer.

Forward AM takes over BASF’s 3D printing activities

Forward AM was launched as a 3D printing subsidiary of BASF in 2017, to expand the chemical firm’s additive manufacturing presence. Since then, the company has grown its 3D printing material operations in various applications.

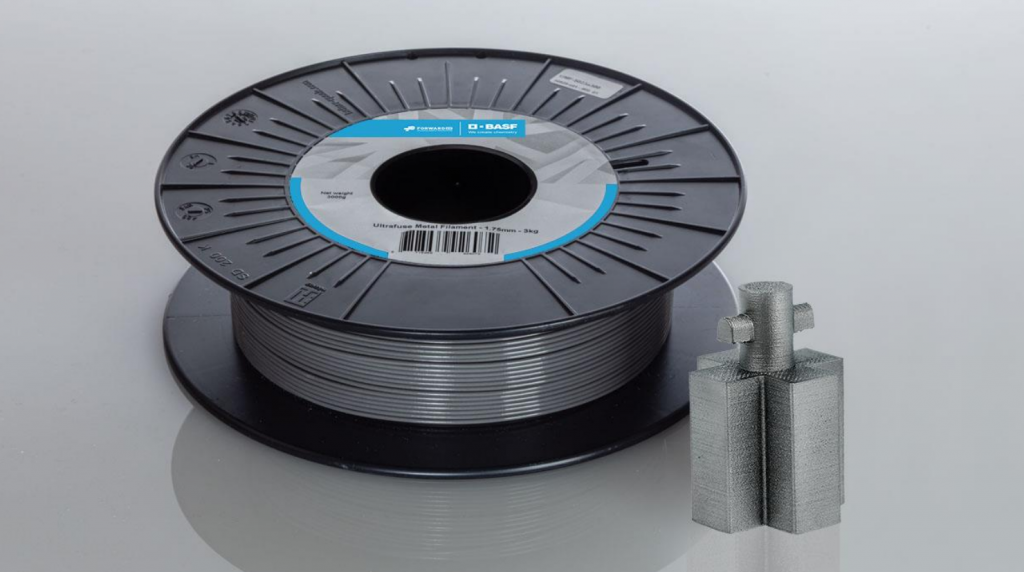

In 2020, it launched the Ultrafuse 17-4 PH metal filament for tooling applications. This 17-4 stainless steel-based material comprises metal powder in a polymer matrix, enabling affordable and safe metal 3D printing on most FDM systems.

The following year, the BASF Forward AM collaborated with Large-format 3D printer manufacturer BigRep to launch a concrete 3D printing material to support the architecture sector. Called ‘Concrete Formwork,’ the PET filament is targeted to complex supports for precast concrete. It allows users to produce these structures at lower costs and with shorter lead times than normal building methods.

More recently, Formnext 2023 saw the materials specialist partner with Farsoon Technologies partnered with Hyperganic to develop an integrated solution for 3D printing lattice structures. This offering was designed to enable the successful production of lattice structures at the first attempt.

The company’s materials and 3D printing technologies have reportedly performed well over recent years, experiencing a consistent 30% annual growth rate since 2022. This growth is said to be more than double the industry average. Having retained its IP and supply chain, the company claims it will meet future demand and fulfil its contractual obligations without disruption.

Back, now the owner of Foward AM, believes it is a “very exciting time to be part of the AM industry.” He outlined that the firm will work to “drive innovation” through continued collaboration with its partners. The newly carved-out company will work to enhance speed-to-market and deliver customer-centric solutions through cross-industry collaborations.

“This new venture emphasizes our continued commitment and dedication to providing expedient and robust AM solutions, focusing on the success of our customers and partners. Together, we are proving that AM technologies are integral to the future of manufacturing. Together, we will keep moving forward,” added Back.

Carving out new 3D printing companies

Forward AM Technologies is not the only new company to join the 3D printing industry. Earlier this year Spanish 3D printer manufacturer BCN3D launched Supernova, a carve-out of its Viscous Lithography Manufacturing (VLM) business unit.

Completed in Q4 2023, this move has seen Supernova become a completely independent company in the additive manufacturing space. The company is led by Roger Antunez as CEO, who had served as General Manager of BCN3D since 2019. Marta Mico, the former VLM Head of Business Development at BCN, co-founded Supernova.

Headquartered between Austin and Barcelona, Supernova targets end-use, high-volume production applications. To achieve this, the company combines high-performance materials, a scalable resin 3D printing platform, and competitive cost per par. Upon launch, over 500 companies had already signed up for the VLM Technology Adoption Program, including Puma, Saint-Gobain, Orbea, Hutchinson, and Prodrive.

More recently, Israeli electronics 3D printer manufacturer Nano Dimension has completed the acquisition of Desktop Metal, a Massachusetts-based industrial 3D printer manufacturer. The all-cash transaction, worth as much as $183 million, will see the creation of a new combined company headed by Nano Dimension’s Yoav Stern as CEO. Ric Fulop, Desktop Metal CEO, will join the C-suite and board of directors.

The new firm will reportedly boast a strong financial profile, with joint FY 2023 revenue of $246 million, 28% of which is recurring. Fulop views the new venture as “one of the most formidable companies in our space,” and a “very formidable juggernaut with a bright future.” Along with Stern, he claims it will drive a transition from prototyping to end-use, “mass production.”

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows a part 3D printed in material developed by BASF Forward AM and Sculpteo. Photo via BASF Forward AM.