Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

3D printing software developer Dyndrite has introduced an upgraded release of its LPBF Pro software, designed for Laser Powder Bed Fusion (LPBF) machines.

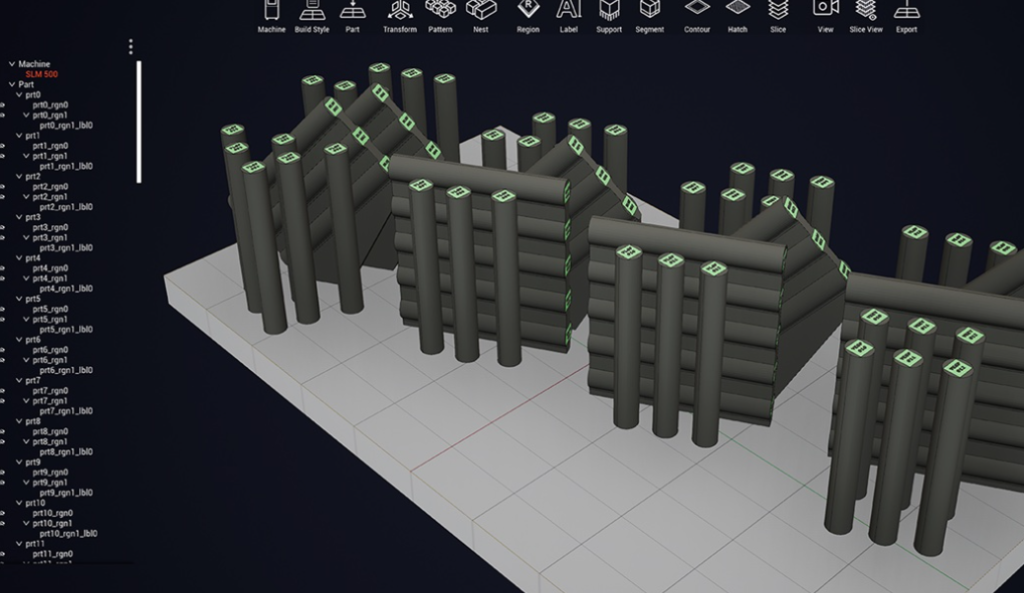

Utilizing GPU computational power, Dyndrite LPBF Pro provides metal AM companies with advanced capabilities and is compatible with several major manufacturers, including Aconity3D, EOS, Nikon SLM Solutions, Renishaw, and Xact Metal. Allowing for the creation of complex parts, this software also facilitates the acceleration of build strategies and the automation of build preparation processes.

The 3D printing software is designed to enhance productivity, accuracy, traceability, and consistency in materials development and serial production for AM while addressing the increasing data demands of 3D printing. Earlier, Dyndrite introduced a VIP Onboarding program for this software.

“Over the past six months, we’ve collaborated closely with the members of our Early Adopter Program to ensure our toolkit addresses their most significant technical challenges and process control needs,” said Steve Walton, Head of Development for Dyndrite. “Their feedback has been invaluable, and is incorporated in this latest release. We are excited to see what our users will be able to accomplish with these new tools.”

Better support control, toolpath functionality, and user experience

Among its key features, Dyndrite LPBF Pro facilitates the development of new materials, alloys, and multi-material parameter sets. It supports various layer heights and can print detailed geometries, including small features, thin walls, domes, and cantilevers. The software also offers advanced surface roughness controls and techniques for creating support-free print strategies. It is widely used across industries such as aerospace, defense, rocketry, automotive, energy, and medical fields.

The latest version of Dyndrite LPBF Pro includes several new enhancements. In terms of support geometry, the software now provides greater control over the interfaces between parts and build plates, with APIs designed for part avoidance and connection. The toolpath functionality has been expanded with advanced tools for heat exchangers and thin walls, beam stirring, and multi-optic strategies, along with highly accurate build time estimations.

For trajectory planning, the software is equipped with novel APIs that address multi-laser constraints. Additionally, Dyndrite LPBF Pro offers an integrated documentation and scripting interface that educates users as they work, enabling quick adoption regardless of prior experience.

As per Dyndrite, Renishaw QuantAM users can leverage the 3D Volumetric Segmentation tools in Dyndrite LPBF Pro to analyze and apply multiple parameters to parts. This functionality has enabled the successful printing of support-free coupons with overhangs reaching 30°, highlighting the software’s sophisticated capabilities.

At Rapid + TCT 2024, companies including Equispheres, and Additive Manufacturing Solutions (AMS) showcased parts produced with Dyndrite LPBF Pro, demonstrating the software’s versatility and performance. Equisphere (Booth 1361) displayed aluminum parts, both with and without the use of Dyndrite LPBF Pro, highlighting high productivity and superior surface finish control.

At Dyndrite’s Booth 2031, AMS showcased parts printed with a jointly developed “Continuous Offset Contour” approach addressing over-energized zones typically caused by traditional vector path and hatching strategies, which can lead to peeling or build failures in motorsport parts with thin wall ducts. Aconity3D also exhibited Equispheres’ aluminum prints, whereas parts printed on Nikon SLM Solutions, Renishaw, and EOS machines were featured.

Efficiency in AM Workflow with novel software capabilities

Updates to AM software ensure users experience increased reliability, improved print quality, and expanded capabilities, while also addressing security concerns and enhancing overall user experience. Keeping software updated thus supports the improvement and efficiency of AM technologies.

With significant updates to the nTop 4 software, nTop sought to address AM challenges by enhancing design flexibility reducing time-to-market, improving part quality, and lowering costs. Key features include Field Optimization for generative design, Implicit Interop for seamless data transfer, and nTop Automate for design automation.

These updates aim to streamline complex AM processes, enabling engineers to achieve higher performance and efficiency in designing and manufacturing intricate parts. Additionally, nTop Accelerate programs support adoption through personalized training and workshops, facilitating rapid value delivery in organizations.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What are the 3D printing trends the industry leaders expect to see this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Dyndrite LPBF Pro streamline materials and process development. Photo via Dyndrite.