Shenzhen-based 3D printing software development company CBD-Tech has launched its new CHITUBOX Dental slicer software specifically designed for the dental industry.

This software is designed to enhance workflows and boost efficiency for professionals working with dental models, splints, surgical guides, crowns, bridges, and more. With a robust user base exceeding 1.8 million for its CHITUBOX slicer series, CBD-Tech aims to address common issues in existing dental slicers with this new launch. The company’s goal is to create a more efficient and stable workflow for dental professionals and collaborate with global users to further streamline dental 3D printing processes and foster industry development.

“At CBD-Tech, we’ve always been passionate about empowering creators,” says CBD-Tech. “With CHITUBOX Dental we’re empowering dental professionals to unlock the full potential of 3D printing. Imagine streamlined workflows, faster production, and exceptional results. This is about innovation for the entire dental industry.”

Streamlined workflows with automated pre-processing

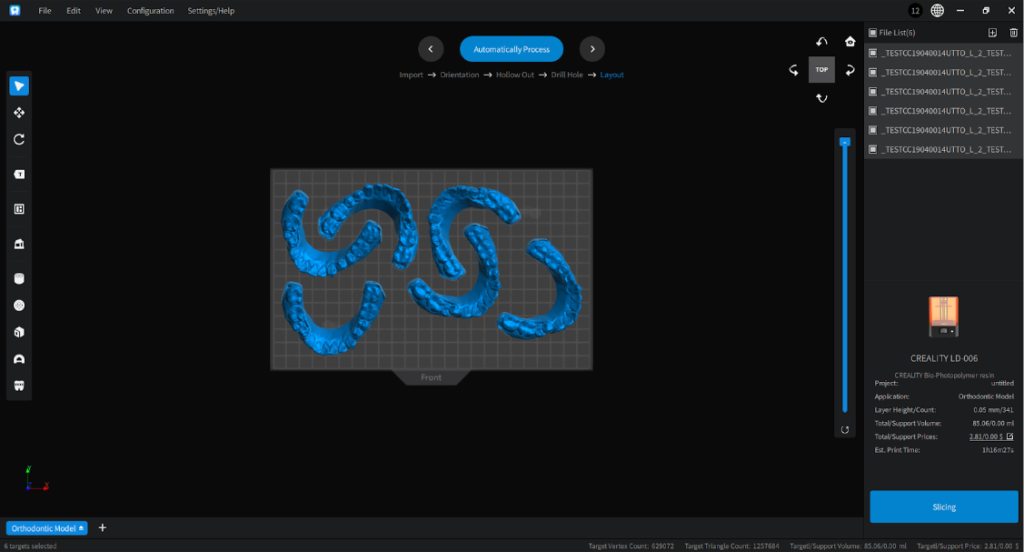

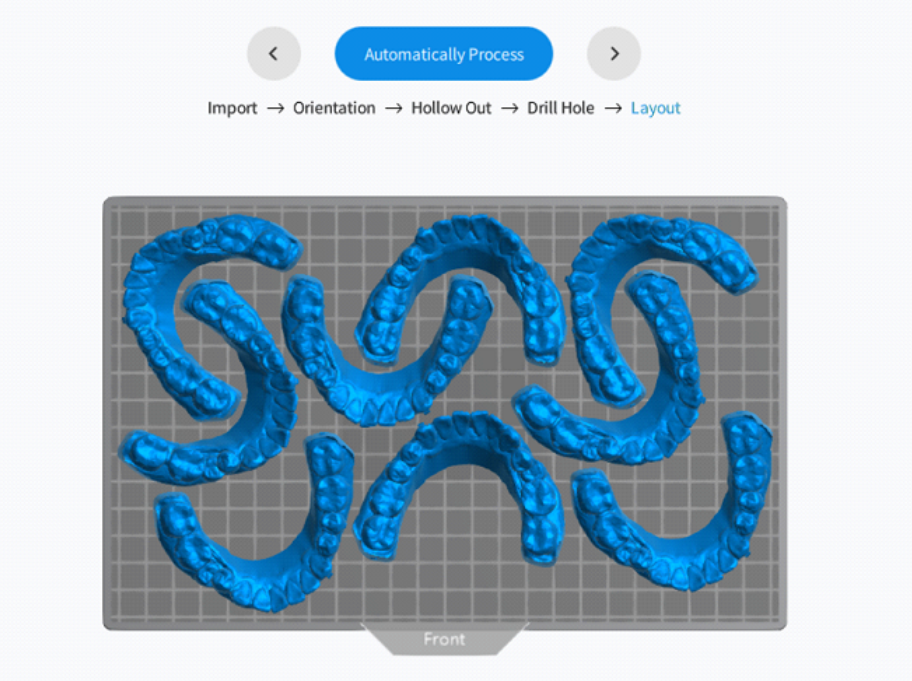

One of the standout features of CHITUBOX Dental is its one-click slicing functionality. This allows users to complete the entire pre-processing workflow, including orientation, hollowing, filling, drilling, layout, and supporting, with a single click.

According to CHITUBOX Lab, this feature can significantly improve production times, with the software reportedly preparing a single crown in just 5.73 seconds, a single surgical guide in 7.13 seconds, and 16 dental models in 44.25 seconds. Additionally, these automated functionalities help enhance efficiency and reduce the learning curve for new users.

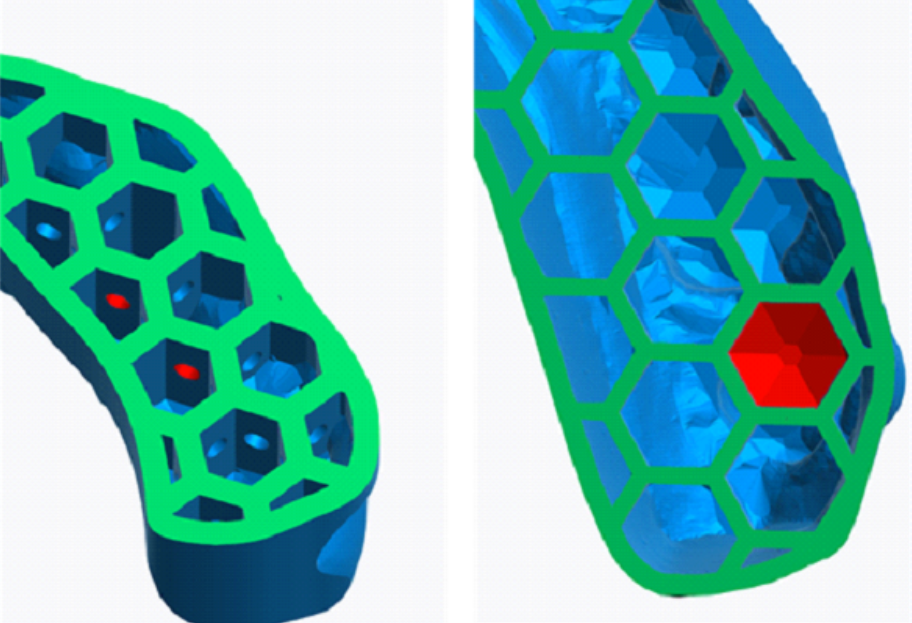

By using tailored algorithms, CHITUBOX Dental avoids generating support structures within porous areas, ensuring adaptation between surgical guides and implants. Additionally, CHITUBOX Dental intelligently places drain holes while avoiding filled structures, which enhances printing success.

Advanced filling and material efficiency

According to CBD-Tech, special designs optimize the filling function. Unique dome structures are integrated into the overhanging areas of hollowed models, preventing printing failures and ensuring model stability without additional support. Internal through holes within hive and grid structures reduce suction forces when the build plate rises, facilitating the removal of excess material post-printing.

As reported by CBD-Tech, CHITUBOX Dental can save 5.1 grams of material per dental model. For a high-volume dental lab producing 2,000 models daily, this could mean a potential daily material saving of around 10 kilograms, which greatly reduces production costs.

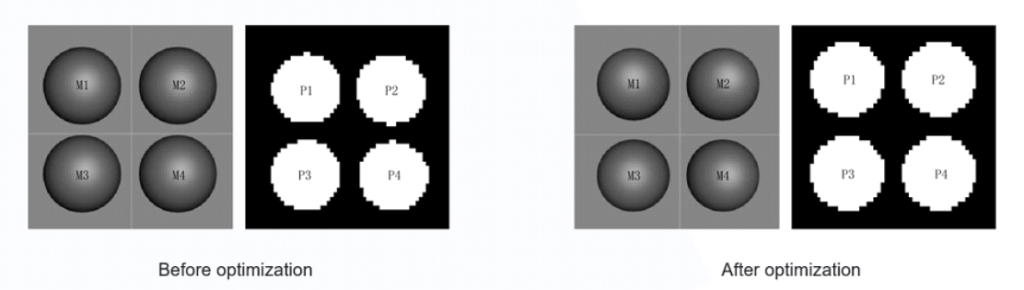

Addressing the limitations of traditional slicers, CHITUBOX Dental optimizes the algorithm to ensure that pixel quality is maintained uniformly across the build plate during the vector-to-raster conversion process. The software incorporates compatibility data from collaborations with printer manufacturers, enabling users to effortlessly select their printer and resin for optimal printing results.

In summary, the company says CHITUBOX Dental is a powerful slicer that improves efficiency and reduces costs for dental professionals. Learn more about CHITUBOX Dental.

Register now for our Additive Manufacturing Advantage online event for insights on AM developments in aerospace, space, and defense sectors from industry leaders!

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows The CHITUBOX Dental Slicer software. Image via CBD-Tech.