3D printing software developer Authentise has partnered with high-performance metals company United Performance Metals (UPM) to introduce its new Vendor Managed Inventory (VMI) platform.

Designed to improve material management, traceability, and efficiency for manufacturers, VMI is said to be the first 3D printing software of its kind.

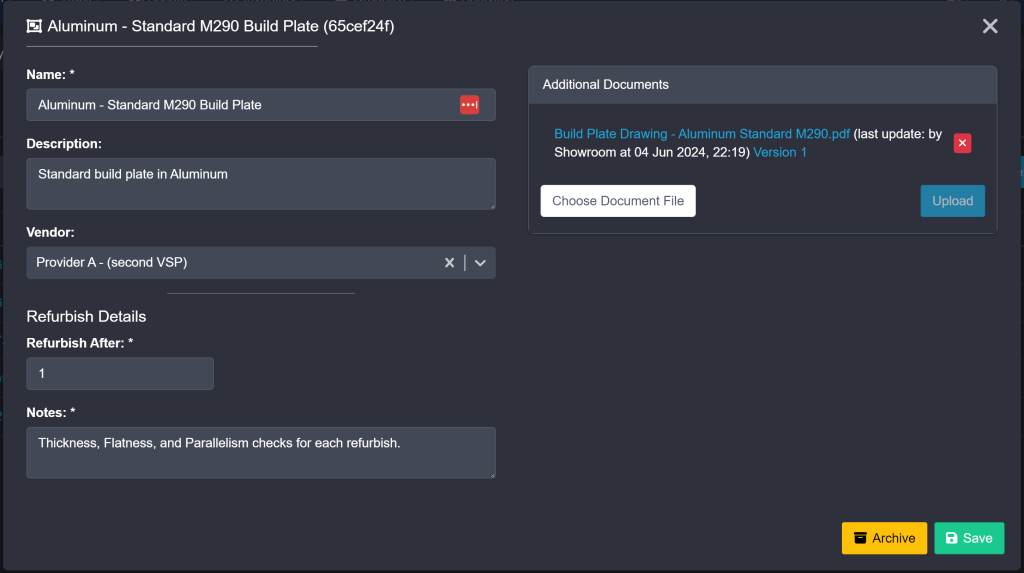

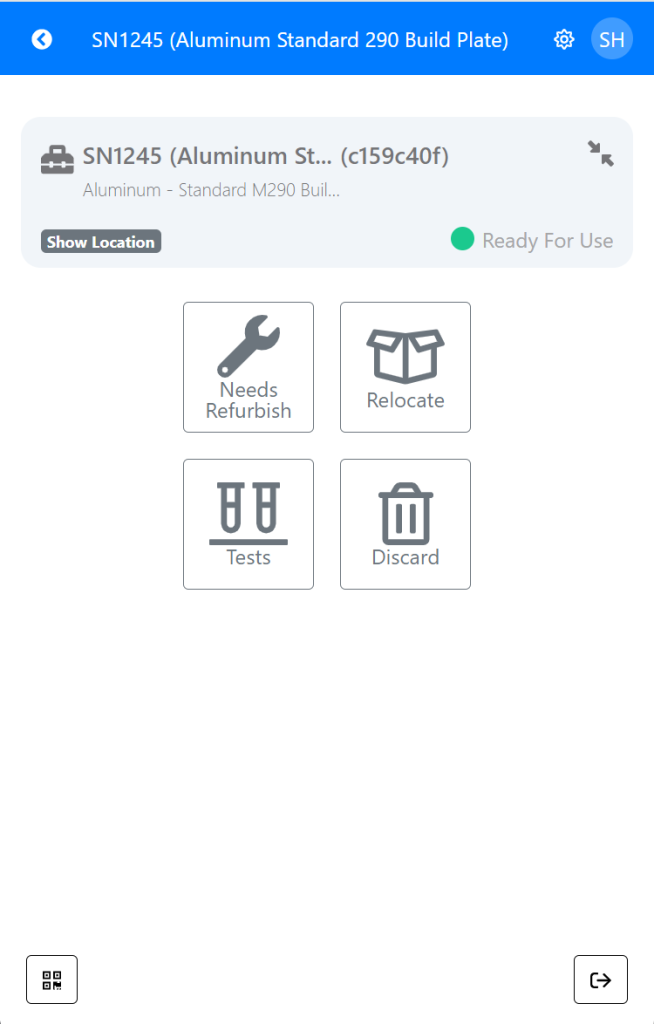

The new software leverages Authentise’s technology to offer comprehensive traceability of key components such as metal build plates or powders. Vendors can track the complete history of these objects, allowing them to guarantee part quality, optimize production, and adhere to strict industry standards.

Authentise and UPM’s new digital VMI also allows users to manage their inventories and ensure materials are readily available for production, without manual intervention.

“We are excited to join forces with United Performance Metals to introduce this transformative solution to the additive manufacturing industry,” commented Andre Wegner, CEO of Authentise.

“VMI is a natural extension of our existing Material Genealogy tools, which already provide detailed traceability record. This extends inventory history beyond materials and outside the walls of the manufacturer. ”

Authentise and UPM launch new Vendor Managed Inventory

According to Wegner, VMI integrates Authentise’s data-driven workflow tool expertise with UPM’s knowledge of high-performance metals and tools. This will reportedly enable manufacturers to optimize their operations and enhance transparency.

The new inventory management software automatically monitors and replenishes build stock. It also features a remote management portal for live monitoring and management of build plate supply. The software allows users to record key build plate measurement data, including thickness, Flatness, and Parallelism.

VMI is advertised as allowing manufacturers to keep consignment stock in the buyer’s warehouse, lowering costs and improving cash flow. This flexibility will reportedly help companies to quickly adapt to evolving market needs, and scale operations more efficiently.

JJ Johnson, General Manager of UPM Additive Solutions, calls the introduction of VMI a “significant milestone for the additive manufacturing industry.” He believes that the new collaborative offering showcases the increasing maturity of 3D printing, reflecting the “growing adoption of advanced technologies to streamline production processes.”

Authentise and UPM have already secured beta customers for their new offering, including direct metal laser sintering and melting (DMLS and DMLM) service provider i3D MFG.

Stephanie Bonfiglio, the company’s Director of Integration, stated that i3D MFG is “thrilled” to be implementing the new VMI platform.

“We look forward to achieving full traceability, automated inventory management, and the agility to scale our production as required,” commented Bonfiglio. She added that VMI could revolutionize the way the firm manages its materials, and will help to streamline its additive manufacturing processes.

As such, Bonfiglio calls the new offering an essential tool for any additive manufacturing firm looking to rapidly scale operations.

Digital inventories enhance additive manufacturing

The 3D printing industry has seen growth in digital inventories and online inventory management systems over recent years. These platforms offer manufacturers environmental, economic and supply chain advantages by digitizing access to 3D printing materials and spare parts.

German 3D printing software developer 3YOURMIND previously launched its Digital AM Inventory module to centralize access to 3D files and production data.

An extension to the 3YOURMIND workflow software, the platform aims to simplify production by offering a cost-effective alternative to storing parts in physical warehouses. Through the digital inventory users can store part specifications and production requirements, visualize 3D models, and conduct repeat ordering with pre-saved material and technology selections.

In 2022, Finnish 3D printing software company SelectAM launched a platform that can identify 3D printable parts from digital inventories. This allows businesses to understand if there is a viable business case for 3D printing an existing component.

This software was designed to increase the adoption of additive manufacturing by highlighting appropriate parts and applications well suited to 3D printing. It features an embedded slicer suitable for all the relevant additive manufacturing processes. It also enables automated material mapping between traditional and 3D printing materials.

Elsewhere, Wibu-Systems offers OMNIPlus, an online 3D printable spare part inventory. Developed with German bus manufacturer Daimler Buses and metal 3D printer manufacturer Farsoon Technologies, the digital inventory allows Daimler and Setra Bus operators to 3D print spare parts as they are needed.

Register now for AMAA 2024 to hear insights from industry experts on additive manufacturing in aerospace, space, and defense.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the Authentise and United Performance Metals logos. Image via Authentise.