The journey of fabricating PDMS devices for microfluidic applications has seen significant advancements over recent years. Moving from traditional techniques like photolithography to more cost-effective alternatives like soft lithography, new research is now exploring the integration of 3D printing and how it can fit into existing device fabrication workflows.

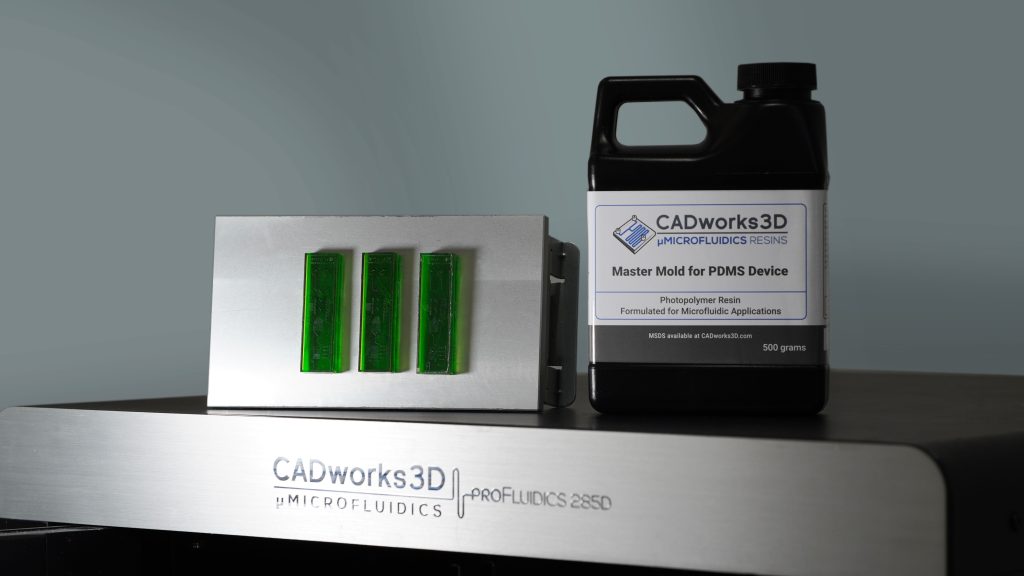

Canadian-based 3D printer manufacturer and 3D material developer CADworks3D is a leader in this space. Combining groundbreaking 3D printer technology with specialized 3D photopolymer materials, CADworks3D has built a complete and efficient 3D printing solution for fabricating PDMS devices. This includes their ProFluidics 285D DLP printer, and their in-house photopolymer resin, the Master Mold for PDMS Device resin.

The Evolution from Photolithography to Soft Lithography

The early days of microfluidic research saw photolithography as the go-to technique for creating microstructures and patterns on microfluidic devices. It involved the use of photomasks, cleanroom facilities and intricate chemical processes to create precise patterns on substrates like silicon wafers or glass slides.

While photolithography provides high-resolution patterning, it does have notable limitations. Creating a single device requires many steps and several different tools and chemicals. Included in this are specialized equipment and cleanroom facilities, making this technique expensive and inaccessible to many researchers or small-scale applications. Moreover, photolithography is not ideal for producing complex designs or three-dimensional structures. It is a single-layer process and creating multilayer structures or 3D microfluidic systems requires multiple rounds of photolithography, alignment and bonding processes that are time-consuming and prone to alignment errors.

Photolithography is primarily suited for processing semiconductor materials like silicon and glass, and is not ideal for materials that are incompatible with the harsh chemicals and high temperatures used in the process. Subsequently, the demand for more accessible and versatile microfluidic devices has grown, and soft lithography has emerged as a game-changer in the industry.

Soft Lithography to Create PDMS Devices

Soft lithography was developed as an alternative to photolithography, addressing many of its predecessor’s limitations particularly in terms of cost, simplicity and material compatibility. It refers to a group of techniques that use elastomeric materials in the fabrication of microfluidic devices, with polydimethylsiloxane (PDMS) being the most prevalent. With it, researchers could now prototype and fabricate microfluidic devices more quickly and efficiently.

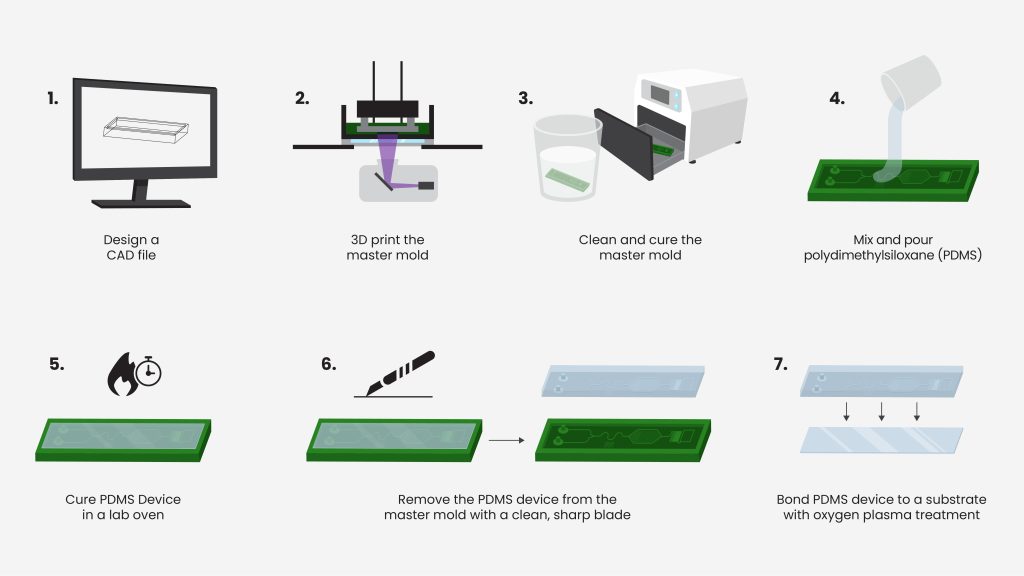

Soft lithography starts with the creation of a master mold, oftentimes using photolithography. This master mold contains a negative relief of the desired microfluidic features such as channels and chambers. PDMS is then mixed, poured onto the master mold, and cured to create a replica of the master mold. This replica is peeled off the master mold and bonded to a substrate through oxygen plasma treatment or chemical bonding to create a sealed microfluidic device. Its greatest advantage is the ability to produce multiple microfluidics PDMS devices from just one master mold in a short period of time.

Accelerating the Soft Lithography Process with 3D Printed Master Molds

The integration of 3D printing into the soft lithography workflow represents the next step in the evolution of microfluidic device fabrication.

Photolithography is the most common master mold fabrication technique. However, as discussed, the photolithography process is expensive, time-consuming and leaves much to be desired in building (a) complex designs and (b) three-dimensional features – all in a timely manner. 3D printing addresses these challenges by offering a new, efficient method to creating master molds.

3D printing enables the rapid prototyping of microfluidic device designs. It allows researchers to quickly iterate and modify their designs by 3D printing new master molds within one working day, reducing the time and costs associated with traditional mold fabrication. Microfluidic devices become highly customizable where researchers can easily create bespoke microstructures and adapt them as needed to meet specific application requirements.

The CADworks3D Solution for PDMS Devices

CADwork3D has developed a 3D printing solution tailored to the fabrication of PDMS devices. Researchers are given the ability to 3D print, clean and cure a master mold in just a few hours, and within one working day a PDMS device can be casted and ready for bonding to a substrate.

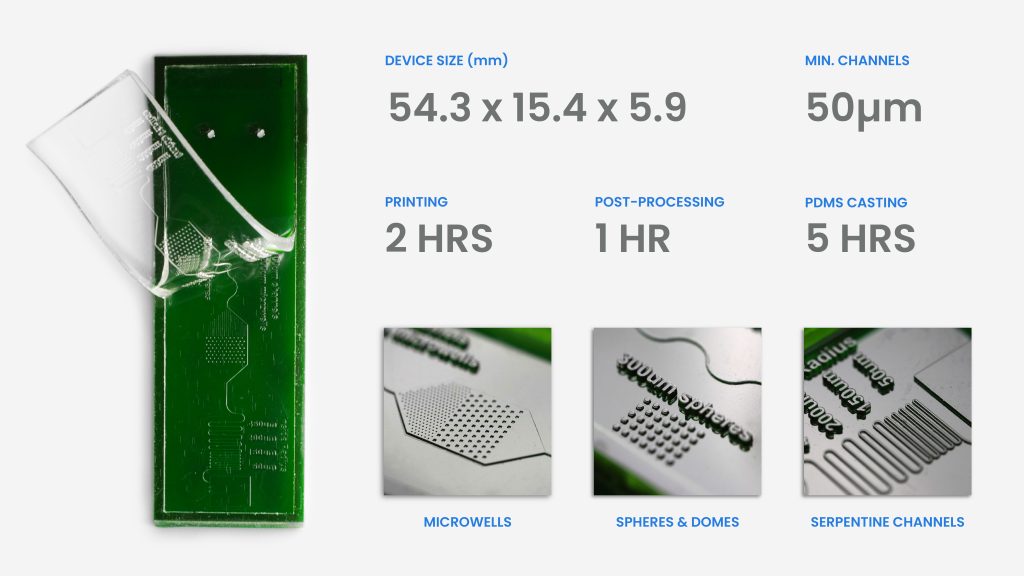

The ProFluidics 285D is CADworks3D’s flagship DLP 3D printer. While most 3D printers available on the market are repurposed from other industries, the ProFluidics 285D was designed specifically for microfluidics applications. It operates with a unique technology, known as the dynamic pixel advantage. This allows users to print microfluidic devices with superior 3D printed features, and 3D printed devices closely resemble the intended design as shown on the original CAD file. When compared to other 3D printing platforms, the ProFluidics 285D demonstrates smoother surface finishes and properly resolved curves to produce intricate three-dimensional micro features such as serpentine channels, micro wells and domes.

When used in conjunction with CADworks3D’s Master Mold for PDMS Device Resin, users are able to build master molds with 50µm open channels and surface roughness value (Ra) of 0.18µm. This photopolymer has been formulated to reduce the amount of steps required to fabricate microfluidic PDMS devices. It does not require release agents, coatings or other pre-treatment processes for a successful PDMS cast. 3D printed master molds are able to withstand the temperatures needed to properly cure the PDMS. According to statistics provided by the Kelley Lab from the University of Toronto, with proper care, one 3D printed master mold can be used to create well over 500 PDMS devices. Additionally, 3D printed master molds do not leech any chemicals, allowing casted PDMS devices to retain their biocompatible properties.

By combining soft lithography with 3D printing, researchers gain access to rapid prototyping capabilities and the ability to create highly customized, intricate three-dimensional microfluidic devices. This integration opens doors to innovative applications across various scientific disciplines and industries, bringing us one step closer to more accessible and tailored microfluidic solutions at a fraction of the cost of traditional methods.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a peeled PDMS device fabricated with CADworks3D’s 3D printed master mold. Photo via CADworks3D.