3D printing software developer Dyndrite has announced a VIP Onboarding for its software, dubbed Dyndrite LPBF Pro.

This software is designed to enhance the capabilities of Laser Powder Bed Fusion (LPBF) professionals. Having brought unprecedented advancements to 3D metal printing, it also offers improved part printing capabilities, faster build rates, and cost savings. Additionally, the software seamlessly integrates with various 3D metal printing machines, including Aconity3D, Renishaw, SLM Solutions, and other leading models. Notably, Dyndrite is a valued member of the EOS developer network. Visitors can explore Dyndrite’s 3D printing technologies in Hall 11.1 stand F51 at the Formnext 2023.

Harshil Goel, CEO of Dyndrite, says, “In AM, software has become the bottleneck limiting industrial users from adopting and maximizing the value from AM technologies. Dyndrite’s mission is to break this bottleneck by equipping AM engineers with tools that make them effective at their job. These tools naturally deliver precision, traceability, and repeatability, serving not only those pushing the boundaries but also those seeking an on-ramp as new customers embracing AM as a scalable and reliable manufacturing process.”

Advancing metal 3D printing beyond traditional limitations

According to the company, metal 3D printing is anticipated to grow by 23-30% annually, cementing its position in additive manufacturing. The industry sees a heightened demand from defense, aerospace, rocket, and automotive sectors for advanced tools, aiming to optimize processes, enhance 3D printing efficiency, and maximize material value. Dyndrite LPBF Pro caters to evolving industry needs, overcoming limitations in outdated formats such as STL and legacy applications reliant on manual interfaces and tribal knowledge, says the company.

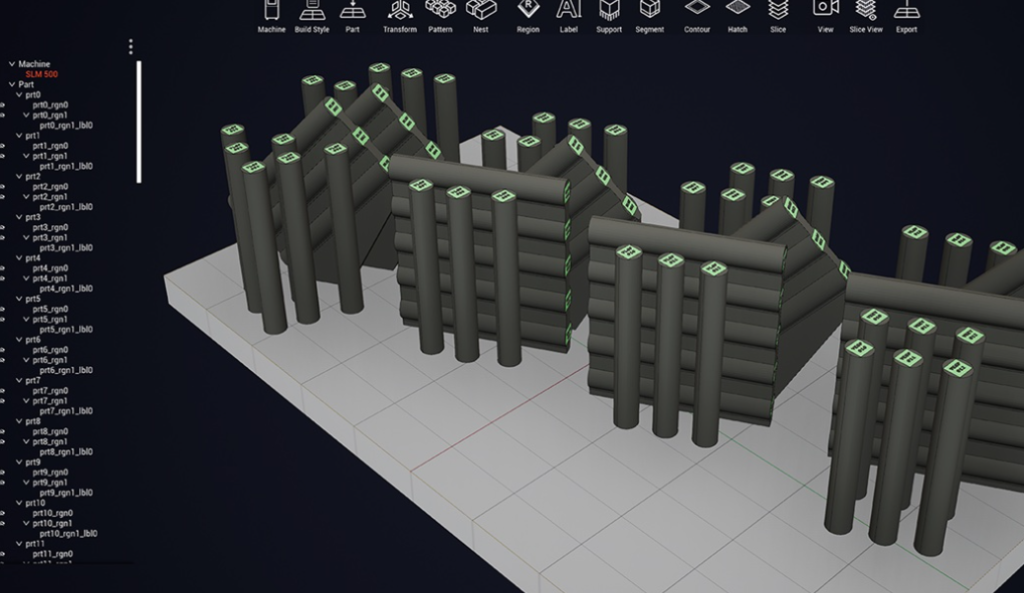

Dyndrite LPBF Pro provides users with unmatched control, utilizing CPU and GPU-powered performance for complex geometry and computational challenges. It simplifies print preparation while allowing materials experts to experiment and innovate, streamlining qualification processes for quality engineers. Kevin J. Brigden, AMG Applications Engineering Manager at Renishaw, emphasized the use of volumetric segmentation to intentionally introduce non-conformance in specific areas of 3D geometry. He pointed out that the QuantAM API’s capability to fully control RenAM500 series laser parameters allows for simulating process degradation by deliberately adjusting laser parameters in these areas of interest. Brigden highlighted this as an initial step, with plans to leverage machine learning to apply this information effectively.

Utilizing Dyndrite’s advanced geometry region segmentation, complex toolpaths for Renishaw machines can be easily generated, surpassing the capabilities of other software. Through a Design of Experiments, the company systematically controlled and varied laser power along a critical functional area, showcasing how optimal print parameters can be systematically determined. This approach opens up the potential for enhanced performance and faster part production, particularly beneficial for multi-laser systems.

“Renishaw has followed Dyndrite with interest since their launch. Upon receiving Dyndrite LPBF Pro with Quantum integration we immediately wanted to demonstrate how this connection could potentially increase the robustness of the certification of production processes,” said Brigden.

Dyndrite advances metal 3D printing

Dyndrite and UPM Additive Solutions partnered to develop “smart” metal build plates for the metal 3D printing sector. Dyndrite says, the plates are vital in metal 3D printing but often lack critical data. This collaboration aims to introduce data intelligence to optimize build plate design, improve adhesion of metal powder, enhance printing accuracy, and identify defects for better quality control. Dyndrite also showcased its LPBF Materials and Process Development software at RAPID + TCT 2023, compatible with major metal 3D printing systems.

Dyndrite also joined forces with MIMO Technik and ASTRO Mechanical Testing Laboratory aiming to streamline and automate additive production and validation, focusing on processes related to 3D printing metal components for various applications in aerospace, defense, and more. Dyndrite’s software will be used to codify construction recipes for repeatability and traceability. It seeks to model techniques for LPBF machines in additive manufacturing, reducing costs and time for calibration and validation. Dyndrite’s GPU-powered software enhances build rates, part quality, and support strategies.

Read all the 3D Printing Industry coverage from Formnext 2023.

Voting has now started for the 3D Printing Industry Awards 2023. Cast your vote now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows Dyndrite LPBF Pro streamline materials and process development. Photo via Dyndrite.