Researchers at the Italian Institute of Technology (IIT) have developed a robotic hand that uses SLA 3D printed artificial muscles to grip objects with human-like efficiency.

The lifelike limb is powered by a series of GeometRy-based Actuators that Contract and Elongate or ‘GRACES,’ 3D printed from a resin membrane that allows them to stretch and contract like muscles. Weighing just 8 grams, these tiny actuators can lift up to 1,000 times their own weight, and when integrated into a robot hand, they’ve shown the ability to bend its fingers, twist its palm and turn its wrist.

3D printing-based biological mimicry

The natural world is filled with examples of animals and plants that have evolved cellular structures with desirable strength, weight and durability qualities, which continue to serve as inspiration to material scientists and engineers alike. In order to recreate these properties in artificial structures and robotics, researchers have often turned to 3D printing, and in doing so, pulled off some impressive biomimicry.

At Zhejiang University, scientists have developed 3D printed cuttlefish-inspired structures which mimic the sea creature’s unique energy absorption capabilities. In fact, the team’s early models are so resistant to compression, that they’re capable of withstanding up to 20,000 times their own weight in deformation. Likewise, engineers at the National Taiwan University of Science and Technology have FDM 3D printed sea urchin shell-shaped lattices that don’t require any support materials.

Elsewhere, in soft robotic attempts at biomimicry, researchers have deployed actuators capable of converting energy and electric signals into motion, in the creation of robots with lifelike movements. A team at Yamagata University have come up with a fully-3D printed soft actuator as the basis of a jellyfish robot, while scientists in China have moved towards limb production by 3D printing a soft robotic finger.

Through effectively combining these approaches, the IIT team says it could be possible to 3D print soft actuators that are strong and flexible enough to effectively “integrate with natural and social environments,” in applications ranging from biodiversity conservation to elderly care. As such, the team consider their robot hand prototype to be a first step towards making such devices easier to create.

Developing a GRACE-ful robotic hand

According to the IIT researchers, artificial actuators have now reached a point in their development at which they’re capable of achieving the same contraction performance as biological muscles. However, in their paper, the team add that it remains very difficult to recreate the “versatility and grace of movements” made possible by the complex arrangements of muscles inside the human body.

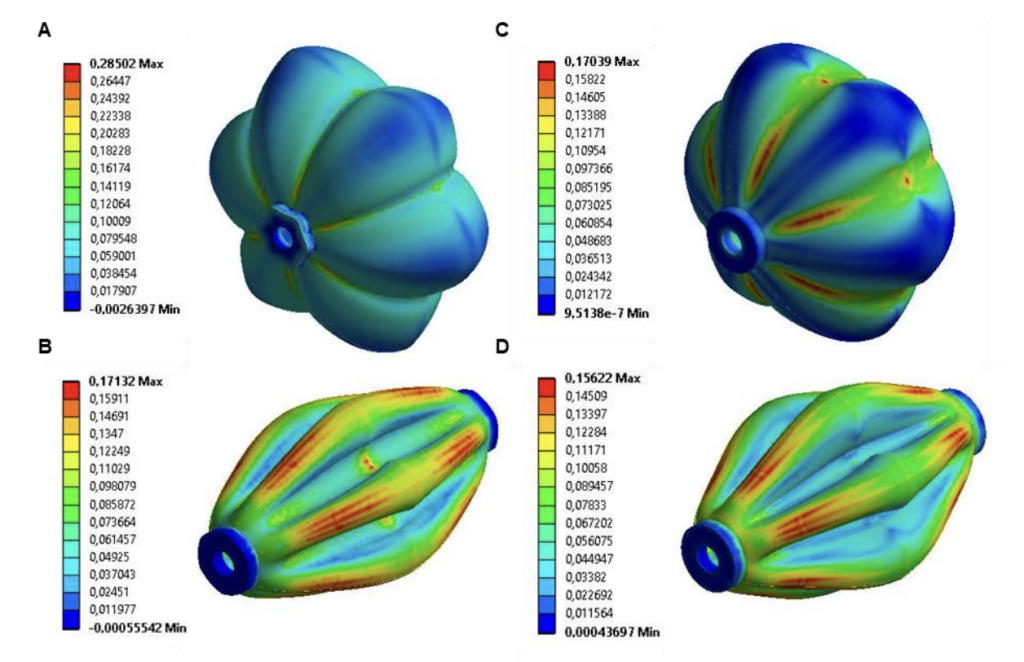

To get around this, the scientists have essentially developed artificial muscles. These GRACEs, composed of a single-material pleated membrane, are built from the ground up to contract and extend using a mathematical model. As a result, the actuators are able to perform as intended without the integration of strain-limiting elements.

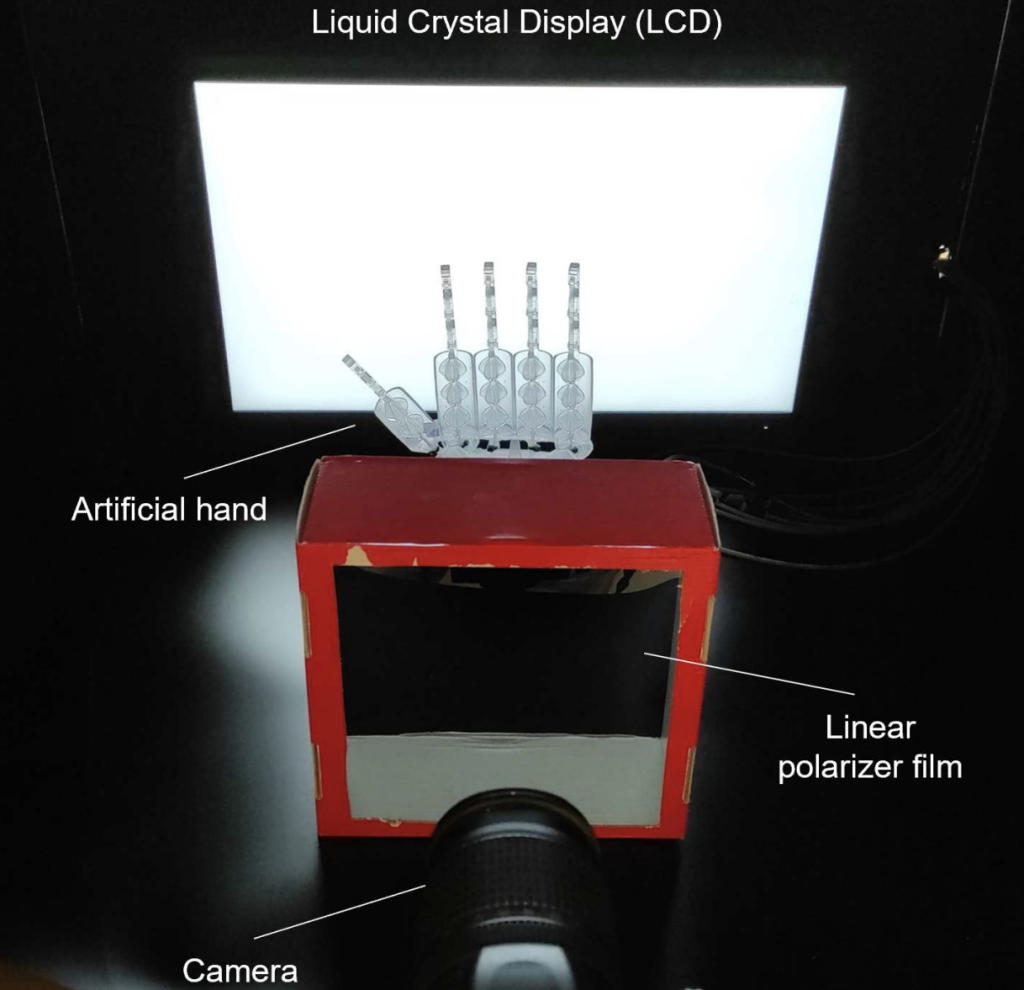

3D printing their GRACEs using a Formlabs Form 3 3D printer also allowed the researchers to integrate pleats into the devices’ membranes that fold and unfold, giving them the flexibility and strength needed to withstand repeated deformation. In practice, the team has tested the actuator’s capabilities by using them to lift increasingly heavy items, both on their own and in groups.

As it turned out, depending on the parameters of the material used to make the devices, they were capable of lifting objects several orders of magnitude heavier than themselves. In one case, an 8-gram prototype GRACE even managed to lift an 8-kilo weight, leading the scientists to consider their potential as a means of mimicking real muscles and body parts.

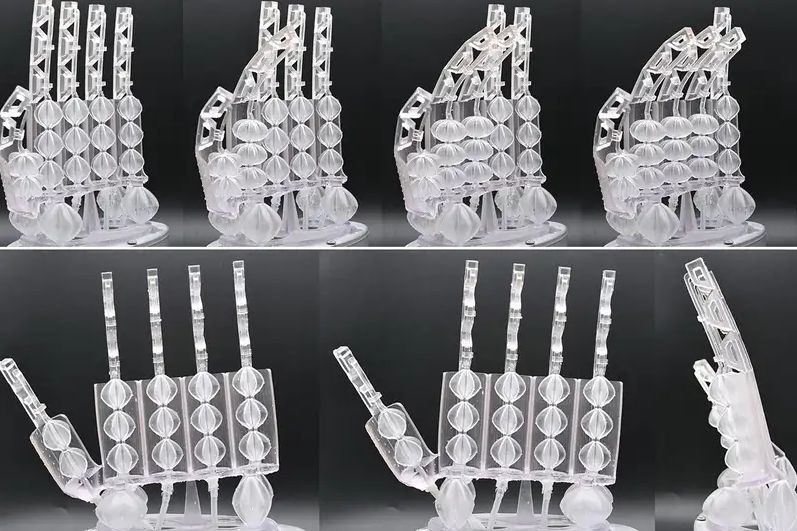

Aiming to test this theory, the researchers opted to connect 18 differently-sized actuators to create a robotic hand and wrist. By applying pressure to each of the 3D printed membranes, they found it possible to operate the hand with human-like movements and efficiency. Having successfully tested their approach, the team say it that it proves it possible to 3D print functional muscles in a single production step.

“The GRACEs can be fabricated through low-cost additive manufacturing and even built directly within functional devices, such as a pneumatic artificial hand that is fully three-dimensionally printed in one step,” concluded the team in their paper. “This makes the prototyping and fabrication of pneumatic artificial muscle–based devices faster and more straightforward.”

The researchers’ findings are detailed in their paper titled “3D-printed biomimetic artificial muscles using soft actuators that contract and elongate,” which was co-authored by Corrado De Pascali, Giovanna Adele Naselli, Stefano Palagi, Rob B. N. Scharff and Barbara Mazzolai.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the IIT researchers’ robotic hand complete with 3D printed GRACE actuators. Photo via IIT.