Researchers from Seoul National University have developed a new two-step process for FDM 3D printing that can create parts with specific gradient material properties.

Typically, users can’t achieve precise spatial control over material composition in FDM 3D printing. This is because FDM nozzles can only extrude a single filament at a time.

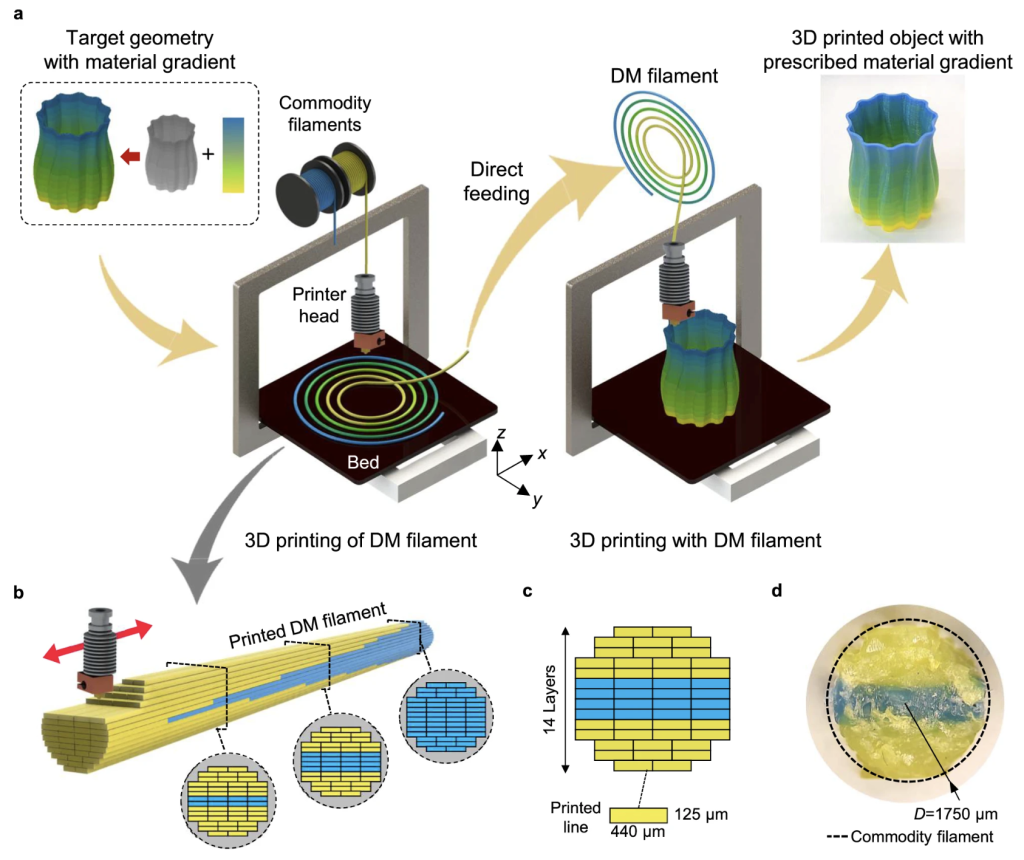

To overcome this challenge, the team 3D printed a “digital material” (DM) by depositing different base materials layer by layer. When this filament is extruded, these materials are homogeneously blended as they pass through the nozzle. This creates the desired functional material gradients within the final part.

According to the researchers’ study, which was published in the journal Nature, this new process produces parts possessing significant variations in properties. For instance, mechanical strength, electrical conductivity, and color can be combined in a way that is not possible with conventional FDM 3D printing.

This new method, called blended FDM (b-FDM), can be achieved using standard FDM 3D printers and filaments, offering a low-cost and accessible way to produce functional gradient materials (FGMs).

According to the researchers, “b-FDM-enabled material gradient programming can facilitate seamless multi material 3D printing and promote robust bonding between different materials with mechanically invisible material interfaces.”

They added that the process “offers a new pathway to unleash the full potential of FGMs for various engineering applications.”

Mixing material properties with b-FDM 3D printing

The researchers’ new b-FDM method sees multiple materials with different properties 3D printed into a single filament, enabling precise control over material composition and distribution.

The filament was 3D printed with a layer thickness of 125 μm and consisted of 14 layers of extruded material. Each layer comprised 2 to 4 3D printing lines, or extrudates, possessing a width of 440 μm. The feedstock was manually changed throughout the 3D printing process, combining different color, strength, stretchability and conductivity properties into the final filament.

According to the Seoul National University team, any commercially available FDM 3D printer and material can be used to fabricate DM filament. It was also 3D printed with a standard diameter of 1.75 mm, making it compatible with all FDM systems.

In the study, the DM filaments were 3D printed using an Original Prusa i3 MK3S from 3D printer manufacturer Prusa Research. This FDM 3D printer was used with a 0.4 mm diameter nozzle and 1.75 mm-diameter feedstock inlet. Good adhesion was achieved by heating the 3D print bed to 70℃ and switching the nozzle temperature between 220℃ and 240℃.

This i3 MK3S was then used to 3D print the DM filament into several test parts. Here, the nozzle was set to the maximum temperature of 240℃ to ensure sufficient material supply.

3D printing parts with gradient material properties

The researchers began their testing by combining conductive PLA (CPLA) with soft and flexible thermoplastic polyurethane (TPU). CPLA is a stiff and brittle material that is electrically conductive due to the presence of carbon black (CB) nanoparticles.

By combining these two materials via the b-FDM method, the team successfully 3D printed parts that were flexible and capable of conducting electricity. After testing different material formulations, they increased fraction strain by up to 168%, with electrical conductivity maintained at strains of up to 69%. Potential applications for this DM filament include stretchable sensing applications and wearable electronics.

The team also highlighted that b-FDM can create diverse color gradients within 3D printed parts. As such, DM filaments offer a cost-effective solution for creating a broad color spectrum with only a few standard filaments. In the study, a single DM filament composed of four base materials was used to 3D print an object with 36 different colors.

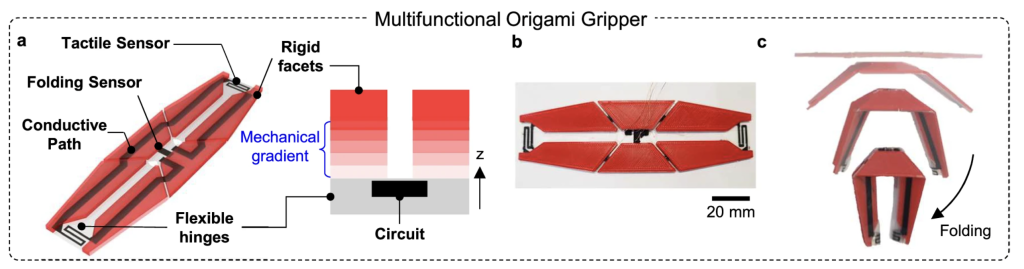

A multifunctional, foldable origami gripper was also 3D printed to demonstrate the value of the b-FDM method. This component incorporated rigid facets, soft hinges, and integrated electrical components including bending and tactile sensors. The entire device was fabricated in one 3D print job using a single DM filament.

The b-FDM 3D printed origami gripper displayed sharp folding along the creases and successfully grasped objects without mechanical failure. Conversely, a conventional FDM 3D printed origami gripper exhibited severe delamination as soon as it was folded.

According to the researchers, these results highlight the capability of b-FDM printing to effectively incorporate a wide range of desired functionalities into engineering systems through material gradient designs.

Looking to the future, they believe that the b-FDM method will serve as a powerful add-on to existing, commercially available FDM 3D printers. It is hoped that increased adoption of this process could push “the boundaries of what is achievable in 3D printing.”

Developments in multi-material 3D printing

Multi-material 3D printing is a growing area throughout the additive manufacturing industry. The Seoul National University team’s b-FDM methodology is unique within the FDM space. Most FDM 3D printers extrude different filaments separately, rather than combining various properties into a single feedstock.

However, studies into inkjet 3D printing have seen researchers mix different resin materials to achieve specific properties in the final part. A team from the University of Colorado Boulder recently conducted one such study, developing “pantone for material properties.” Their findings outline how repeatable 3D printed properties can be achieved by mixing three “primary” materials – a soft elastomer, a rigid plastic, and liquid constituents.

Custom software was used to design hundreds of digital composite material samples. The mechanical properties of the 3D printed samples were then tested, characterized, and mapped. This ultimately allowed users to find the perfect material mixture to achieve the desired properties of their 3D printed part.

Elsewhere, researchers from the MIT Media Lab, Harvard University’s Wyss Institute, and the Dana-Farber Cancer Institute used multi-material inkjet 3D printing to fabricate hybrid living materials.

Called the Hybrid Living Material (HLM) fabrication platform, the team created customized material recipes to combine resins and chemical signals. These signals can activate certain responses in biologically engineered microbes, offering the potential for producing 3D printed medical devices with therapeutic agents.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the b-FDM 3D printing process. Image via Nature.