3D printing firm SUNLU has unveiled the FC01 Filament Connector, a compact device capable of fusing 3D printing filament.

Users of FDM 3D printers are all too familiar with the frustration of having leftover filament that’s too short to be functional. The FC01 overcomes this common issue, allowing FDM filaments to be connected to eke out almost every last centimeter, eliminating material waste and saving money in the process.

The device also unlocks multi-color 3D printing, allowing users to manually combine numerous filaments of different colors into a single print job.

The 3D Printing Industry team got hands-on with the FC01 for an exclusive first look at the new device. This article highlights the key features of SUNLU’s new filament connector, the unboxing experience and operation, and assesses its performance when fusing different materials.

With prices starting at just $44.99, the FC01 is a handy device for hobbyists looking to optimize their 3D printing workflow. The filament connector is available to order now from the official SUNLU online store. According to SUNLU, shipping will begin in September 2024.

Key features of the SUNLU FC01 Filament Connector

The SUNLU FC01 works by heating the ends of two different filaments together within a PTFE sleeve. This melts the filament, causing the material to fuse together as it cools. The device is compatible with PCL, PLA, ABS, PETG, and PA/PC materials with a 1.75mm diameter. It can only fuse filaments of the same material.

The heat block offers quick and accurate heating, reaching 185°C in around 3 minutes. It can achieve a maximum temperature of 240℃, and offers heating accuracy within ±3°C, ensuring reliable and consistent operation for efficient filament fusion.

Through the device’s touchscreen user interface, users can access preset heating parameters for each compatible material. This intuitive user experience makes the FC01 well-suited to all experience levels.

Given the high temperatures required for filament fusion, prospective users may have reservations about the safety of the device. To address this, the FC01 is made from insulation materials that keep the external temperatures cool during the fusion process.

Unboxing and filament connection workflow

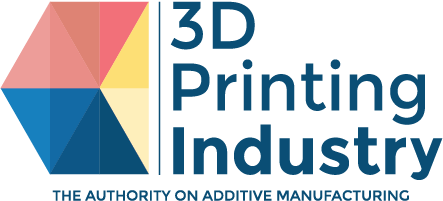

Our SUNLU filament connector came well packaged alongside 2 PLA spools. The FC01 was shipped in a simple and effective compact box, sufficiently protecting the components during transit. Unboxing is straight forward with all contents stored neatly inside cardboard slots.

Along with the FC01 Filament Connector, the package includes a USB power cable and 200 PTFE tubes. The setup process is incredibly straightforward, with the FC01 offering plug-and-play functionality. It takes a matter of seconds to plug the device into a power source and begin the filament connection process.

Sunlu filament connector packaging and box contents. Photos by 3D Printing Industry.

The device features a modern, sleek look consisting of a screen display, a plastic lid to conceal the heatblock and a filament clamp.

All screws are nicely concealed, and the lids are stiffened to prevent them from closing unwillingly. The device is pocket-sized, measuring just 79.5mm x 110mm x 38mm. This makes it easy to transport and integrate into any working environment.

The SUNLU FC01 Filament Connector. Photo by 3D Printing Industry.

A set of simple instructions was included in our package, outlining the steps needed to achieve filament fusion.

Firstly, both filaments should be cut at roughly 45° angles, and inserted into a PTFE sleeve. The desired filament material can then be selected on the touchscreen UI, with the temperature able to be manually adjusted if necessary.

The filament is then placed on the metallic heating block and covered by the heating cover. The device heats up to the required temperature and audibly indicates that fusion is about to begin. Both filaments must then be gently pushed inward until a buzzer sounds, at which point the material can be removed from the heat block.

After the filament has been left to cool for 10-15 seconds, the PTFE-covered section can be pressed into the integrated cutting slot to remove the sleeve. Once removed, the fused filament is ready for 3D printing.

Testing the SUNLU FC01 Filament Connector

According to SUNLU, the filament connector guarantees strong joints and smooth surfaces without affecting 3D print quality, ensuring quality results for detailed and large parts. We put this claim to the test, assessing the usability and performance of the FC01.

It can take a few attempts to achieve perfect results through a trial-and-error process. In our initial attempts, we pushed the filament too hard, causing it to bulge. We noticed that air bubbles can get caught within the PTFE sleeve, causing defects such as dents. This issue often occurred when the two filaments were cut inconsistently.

After perfecting the workflow, we assessed the fusion process of PLA, ABS, PETG, and Nylon filaments.We found that 185℃ is the optimal fusion temperature for PLA filament, providing a smooth and secure connection.

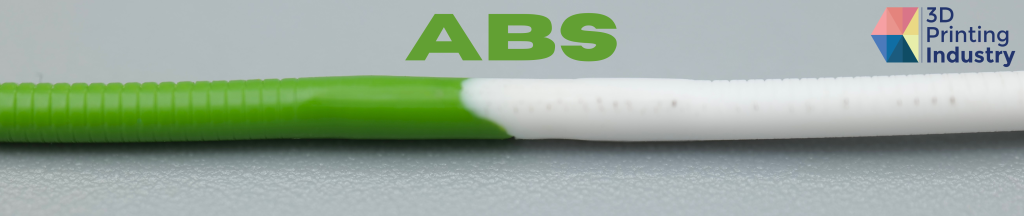

The ABS filament fusion test worked optimally at a temperature of 220℃. No visible defects such as gaps or bulges were present between the two filaments.

Our PETG filament connection worked well at 210℃ with no defects, another successful result for the FC01.

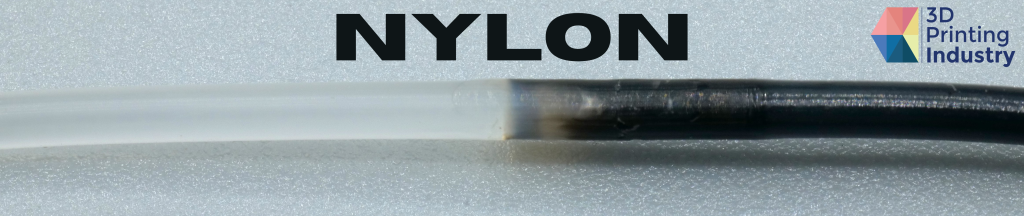

Finally, we confirmed that Nylon fuses well at 235℃. On our first attempt, we noticed some bulging around the outer section of the molten plastic. This occurred as we applied excessive force when pushing the filaments together during the fusion process.

After some trial and error, we successfully resolved this issue and achieved good results. This confirmed that bulging is not a recurring problem with the FC01, and can be easily resolved after some practice with connecting filament. We also noticed that cooling is slow for this material.

Filament connection test results. Photos by 3D Printing Industry.

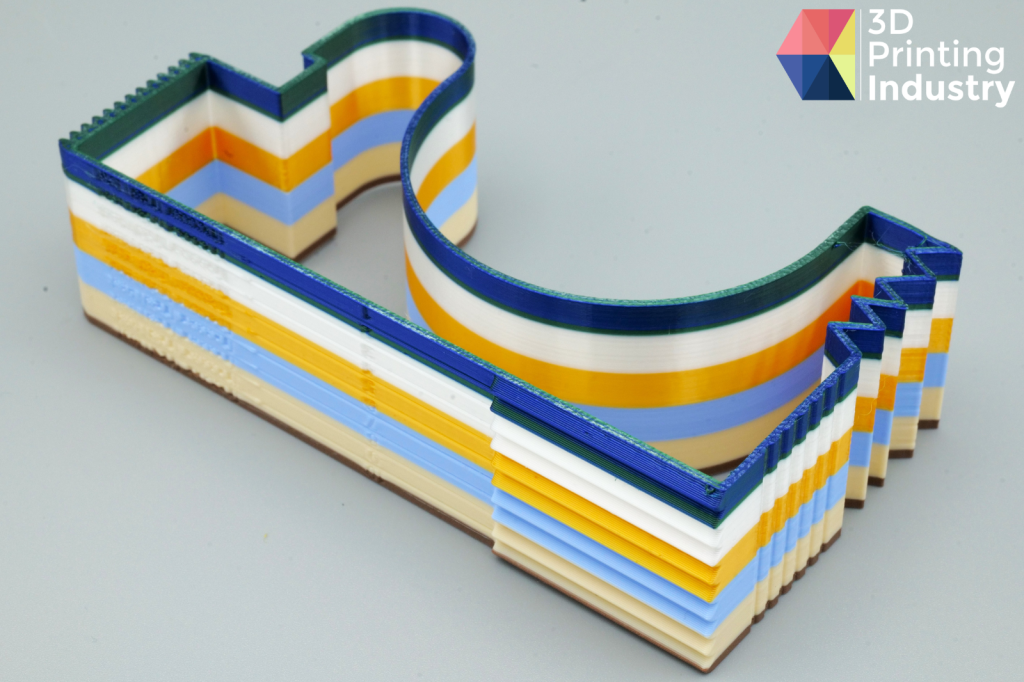

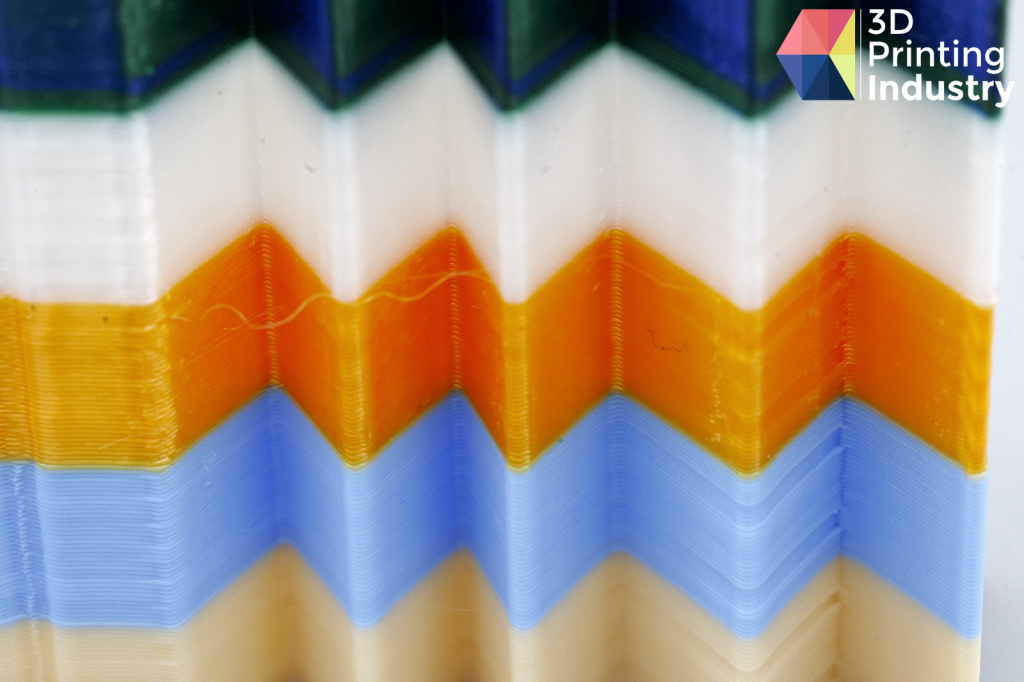

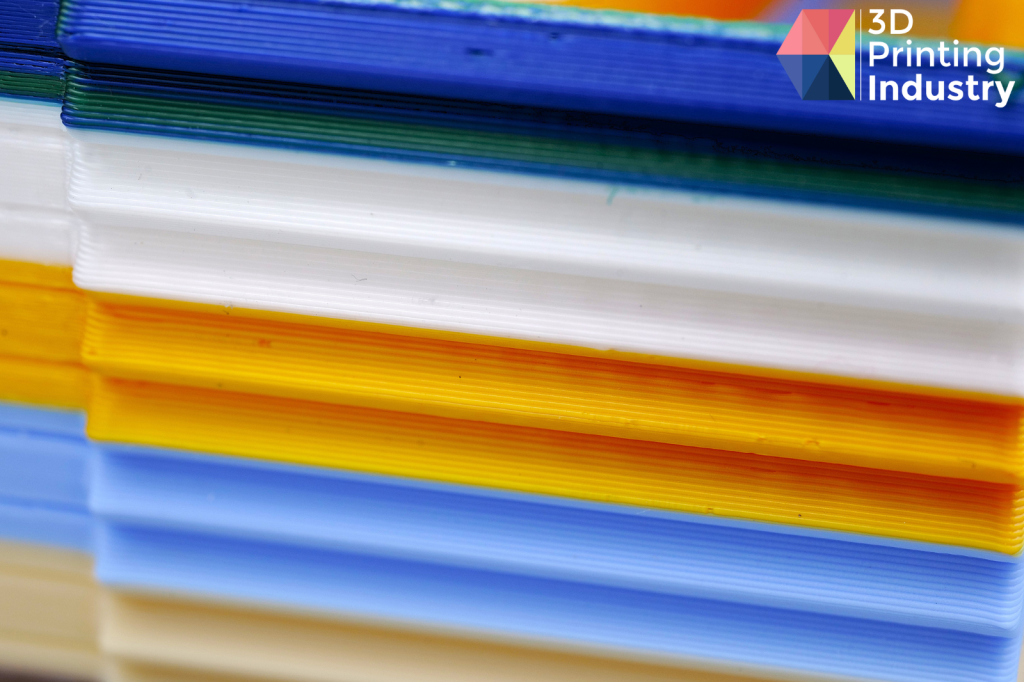

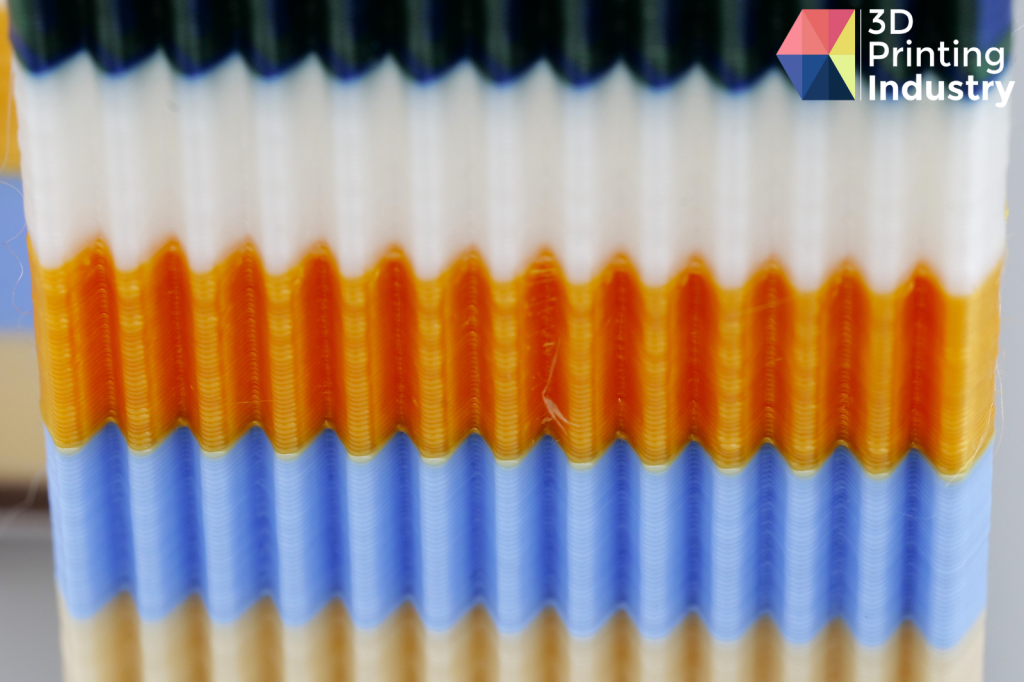

How does fused filament perform during 3D printing? To find out, we fabricated a surface finish test part using six different colored PLA filaments combined with the FC01.

During our initial test, the PLA segments fused together in 120mm sections. Here, we encountered issues with clogging. The 3D print consistently failed around the 50% mark, as the material became obstructed in the nozzle.

This was caused by bulges in the filament where the diameter exceeded the 1.75mm tolerance. These inconsistencies were due to the previously mentioned user error relating to excessive force, as the SUNLU filament connector requires manual input to join the segments.

To improve, SUNLU could add a quality control mechanism to ensure the filament diameters remain within the required tolerance, as bulging leads to a higher likelihood of errors during printing. We believe the addition of a quality control feature would significantly improve the reliability of filament fused in the FC01.

For our final attempt, we used 0.5m PLA lengths, which proved to be much more reliable. The longer segments reduced the risk of inconsistencies passing through the nozzle, minimizing the chances of clogging.

The model displayed a seamless transition between the colours of the fused PLA segments, with no visible defects on the surface. With a little tweaking, the SUNLU FC01 Filament Connector can be used to effectively combine spare filament without compromising 3D print quality or extrusion flow.

Fused PLA 3D printing test. Photos by 3D Printing Industry.

Ultimately, the FC01 stands out as a great addition to the FDM desktop 3D printing market. This affordable and easy-to-use device allows users to achieve notable cost savings by drastically reducing material waste. It also offers a straightforward, albeit rudimentary, solution for achieving multi-color 3D printing.

Our initial testing of this device proved that filament can be fused to achieve high-quality 3D printing.

While the user interface is intuitive, some trial and error is required to realise the best results. What’s more, the lack of a quality control function leaves the results largely reliant on user skill. This can result in 3D printing errors, such as clogging. However, after testing this device for only a few hours, we were able to consistently achieve good results.

The FC01 will be available to purchase in Q4 2024 either as a stand-alone product or in combo offers which include SUNLU filament and filament dryers.

Want to help select the winners of the 2024 3D Printing Industry Awards? Join the Expert Committee today.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the SUNLU FC01 Filament Connector. Photo by 3D Printing Industry.